Safety and sustainability | Performance | Reliability |

|

|

|

Safe, Smart, Sustainable – ANDRITZ Recovery Boilers

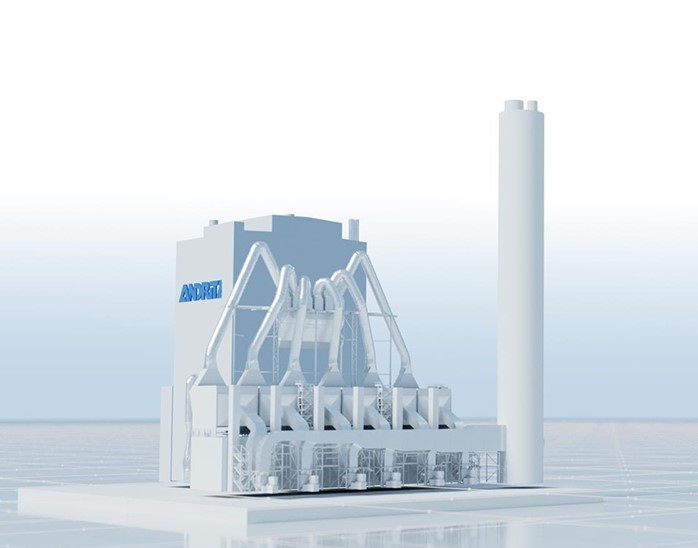

State-of-the-art recovery boiler reliability through innovation and lifecycle services. ANDRITZ world record-breaking recovery boilers for kraft mills are designed to achieve a high power-to-heat ratio to maximize both chemical recovery and energy generation from the recovery process. Combining our process expertise and Metris digitalization technologies, ANDRITZ has developed autonomous recovery boiler solutions to maximize the potential of your recovery boiler throughout its entire lifecycle, supporting your success in the era of digitalization and beyond.

Number one in recovery boilers: Market leadership with decades of experience

A proven track record brings significant value to all recovery boiler customers. With a large installed base, ANDRITZ has supplied recovery boilers all over the globe, including those with the world’s highest capacity. Our smart solutions combine world-leading recovery boiler expertise with the latest Metris digital innovations to increase the level of recovery boiler autonomy. With our high-performance boilers, we can provide customers high lifecycle efficiency with low lifecycle costs. ANDRITZ recovery boilers have world’s highest availability, with long cleanability and durable design. Our recovery boilers are number one in efficiency: high energy, high pressure, high temperature, high recovery. We are a reliable partner and deliver as promised.

Our continuous research and development activities focus on supporting customers in achieving sustainable production with higher capacities as well as higher energy efficiency. At ANDRITZ there is also an added focus on minimizing the consumption of energy, chemicals, and water in a safe and environmentally friendly way. Occupational, environmental, and operational safety are our key priority. New recovery boiler technologies concentrate on the by-products of pulp production and on creating green energy.

ANDRITZ recovery boiler – The heart of the pulp mill

- Chemical reduction rate over 99%

- Production of renewable energy to grid from one unit up to 180 MW

- Tailored to process needs from 100 tds/d up to 15,000 tds/d

ANDRITZ recovery boilers breaking world records

- World´s highest availability

- Uninterrupted operation up to 18 months

- Number one in efficiency

- Minimized atmospheric emissions

Maximized lifetime efficiency in process design

ANDRITZ can undertake the full range of installation, from the execution of part deliveries up to complex EPCC, EPS, and EPC projects of complete islands utilizing an “open book” approach. Strong project orientated organization ensures high quality in all phases of projects, and we are proud of our quick set-ups and extremely fast start-ups. Open and transparent communication and "problem solution" orientation creates a trusting and friendly environment in all our projects.

A full range of value-added recovery boiler services

ANDRITZ recovery boiler services offer a full range of value-added solutions to support the performance of your recovery boiler. We provide solutions for daily operation including inspections and process studies, as well as providing automated solutions for balanced recovery boiler operation. We also offer upgrade and modernization possibilities to increase boiler lifetime and ensure unexpected downtime does not occur. This all supports the process stability, availability, and productivity.

Safety as a top priority: people, environment, products, production, and projects.

We strive for zero accidents. Large recovery boilers’ operational safety requires high-level expertise and experience, and all our operations are carried out in compliance with environmental and quality requirements, with safety being of prime importance. Production of high-pressure and high-temperature steam with world-class capacities requires decades of recovery boiler experience and accumulated special expertise. From the customer point of view this means profitable scalability, operational safety from installation to commissioning and maintenance, and high productivity with uninterrupted recovery boiler running time.

Maximize the potential of your

recovery boiler with

digitalization

Combining our process expertise and state-of-the-art Metris digitalization technologies, ANDRITZ has developed autonomous recovery boiler solutions, an all-in-one Industry 4.0 solution to help your recovery boiler achieve increased stability, availability, productivity, safety, and chemical recovery as well as reduced emissions and OPEX. In addition, an increasing level of autonomy can be obtained gradually through step-by-step integration Metris digitization.