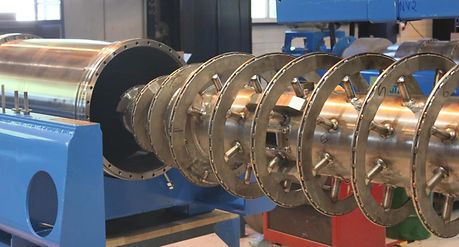

Next generation dewatering equipment - Decanter centrifuge DU

ANDRITZ has developed a generation of decanter centrifuge, bringing you better results than any decanter before: the ANDRITZ decanter centrifuge DU. As a global separation specialist, ANDRITZ has taken a new development step in decanter centrifuges that focuses on performance and benefits for the users in the municipal wastewater market, to handle low concentrated sludge:

High solids dryness: At ANDRITZ, we know that it is essential to obtain the highest possible solids dryness. With the ANDRITZ decanter centrifuge DU, you can expect up to 1% higher dryness than from a conventional decanter.

High capacity: The ANDRITZ decanter centrifuge DU provides up to 20% higher capacity, which will enable you to increase your plant capacity without changing the machine footprint.

Low polymer consumption: Still with the target of improved operating economy, polymer consumption is a key factor in reducing total cost of ownership. In operation, the ANDRITZ decanter centrifuge DU requires 1 kg/TDS less polymer dosage, which results in lower expenses for consumables and allows the polymer dosage to be optimized independently of the decanter operating parameters.

Low energy consumption: Energy consumption is a key element in the process of wastewater treatment. In terms of cost cutting, it is important to ally treatment efficiency with reduced energy consumption. With the ANDRITZ decanter centrifuge DU, save up to 50% more than a traditional decanter centrifuge.