Put our 150 years of OEM experience to work!

Boosted efficiency for iron ore beneficiation, concentrate and tailings dewatering

Changing ore grades. Unpredictable prices. Higher throughputs. How will your business continue to grow despite changing production conditions? Which dewatering equipment will give you reliable performance with minimal residual moisture? What will it take to boost capacity at the lowest possible cost?

ANDRITZ helps you tackle these challenges by providing the industry’s most comprehensive range of customized separation solutions and services for iron ore concentrate thickening and filtration, as well as for economical tailings treatment.

Having served large producers like Jindal in India along with smaller operators such as CML Metals in Australia, we know the complex challenges you face. With thousands of professionals and more than one hundred iron ore solutions in operation, every new challenge is a welcome opportunity. A chance to put our experience, financial strength, and technical resources to work for you. Combined with process simulation technology, machine and process control and proven local service, we are proud to be able to offer the full package from simulation to installation and process optimization.

Do you have questions? Get in contact with us!

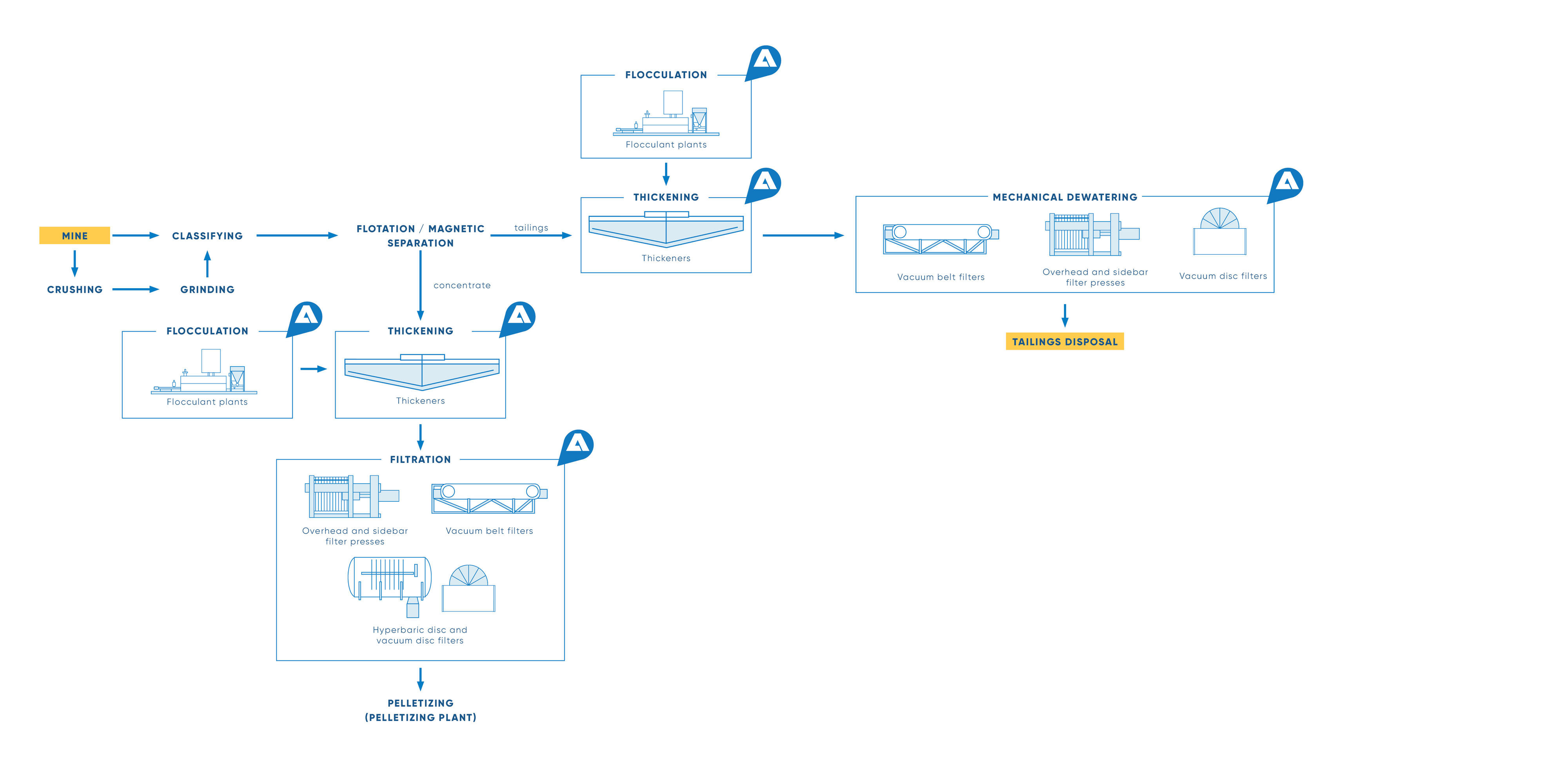

Where we fit into your process

When it comes to thickening and filtration in the iron ore industry, getting the right end product at the right cost is no simple task. Whether it’s magnetite or hematite, goethite, limonite, siderite – or tailings treatment - all types of rock demand their own approach. Thanks to our comprehensive range of separation solutions, we’re able to supply the most suitable processing solutions.

Process line for iron ore from production to tailings treatment

"With just four hyperbaric disc filters from ANDRITZ we can handle more than 1,000 tons of dry solids per hour. No other supplier could match these volumes with such low installation and maintenance costs."

ANDRITZ has invested considerably in expanding its competence in solid/ liquid separation with the acquisition and integration of such well-known OEM's as Bird, KHD Humboldt Wedag, Krauss-Maffei centrifuges, dryers, and filters. The result is an unparalleled level of expertise in separation, together with a complete range of separation systems for the most demanding dewatering applications.

Browse solutions:

Do you have questions? Get in contact with us!