The testliner and fluting mill in Trebsen, Germany, used to send more than 1,000 tonnes a year of useable fibres to its rejects. Challenged by this obvious waste of resources, the mill asked ANDRITZ to help keep the valuable fibres in the production process. With ANDRITZ’s Dilution Water Upgrade in its tail-screening system, Trebsen is now using the fibres it once threw away, saving money instead of wasting it.

“Upgraded it. Switched it on. It all worked.”

The testliner and fluting mill in Trebsen, Germany, used to send more than 1,000 tonnes a year of useable fibres to its rejects. Challenged by this obvious waste of resources, the mill asked ANDRITZ to help keep the valuable fibres in the production process. With ANDRITZ’s Dilution Water Upgrade in its tail-screening system, Trebsen is now using the fibres it once threw away, saving money instead of wasting it.

Julius Schulte Trebsen GmbH & Co. KG makes around 240,000 tonnes of testliner and fluting a year. To do that, it buys about a quarter of a million tonnes of mixed paper and board (1.02), supermarket corrugated (1.04) and new corrugated shavings (4.01). Since mid-2020, thanks to a screening upgrade from ANDRITZ, the mill is buying 1,000 tonnes less of these secondary fibres. This also means 1,000 tonnes less waste to dispose of, this end up in saving almost more than Euro 100,000/year.

The cost of the upgrade? Payback time: 2 months.

Reduce operating costs. Improve screen efficiency.

The Trebsen mill originally installed its current paper machine in the 1960s, from the former GDR-era supplier, VEB PAMA. It was then rebuilt by Bellmer in 2013 (wire and dryer sections extended, new film press installed), and 2015 (new headbox for the top ply).

In fact, the only part of the machine that hadn’t been modernised was the approach section for the bottom ply. And that was why Trebsen turned to ANDRITZ, to resolve issues in the tail screen for the bottom ply, just before the stock approach section.

Most of the time, the mill runs the same raw materials through the stock-preparation systems for both the top and bottom plies of its testliner/fluting. The screening plant for the top ply has narrow slots. But because the bottom ply doesn’t go on display, it is more basic, with screening arranged in three stages, using wider slots compared to the top ply. Despite the larger screening slots, far too much of the stock was being lost, rather than being accepted through the screens. As Steffen Petrich, Investment Projects Manager at Trebsen, explains, “There was no problem with quality or production uptime. Cost was the factor.”

The reject disposal costs have been rising dramatically over the past few years. When it comes to fine rejects, which this particular upgrade dealt with, the waste disposal price has more than doubled in the past five years. Petrich, who is responsible for process and technology costing, implementation and start-up, admits, “We were paying for it twice. We were paying good money to get rid of good raw materials. So we talked to Paul Orban (Product Manager, Screening and Cleaning, ANDRITZ) and Ulf Scott (Customer Service Manager, ANDRITZ), and checked the condition of our screening process. They have been our partner for screens for years. We’ve known Ulf Scott and Paul Orban for a long time.”

The first discussions and laboratory analyses took place in November 2018, and the order was placed in June 2019.

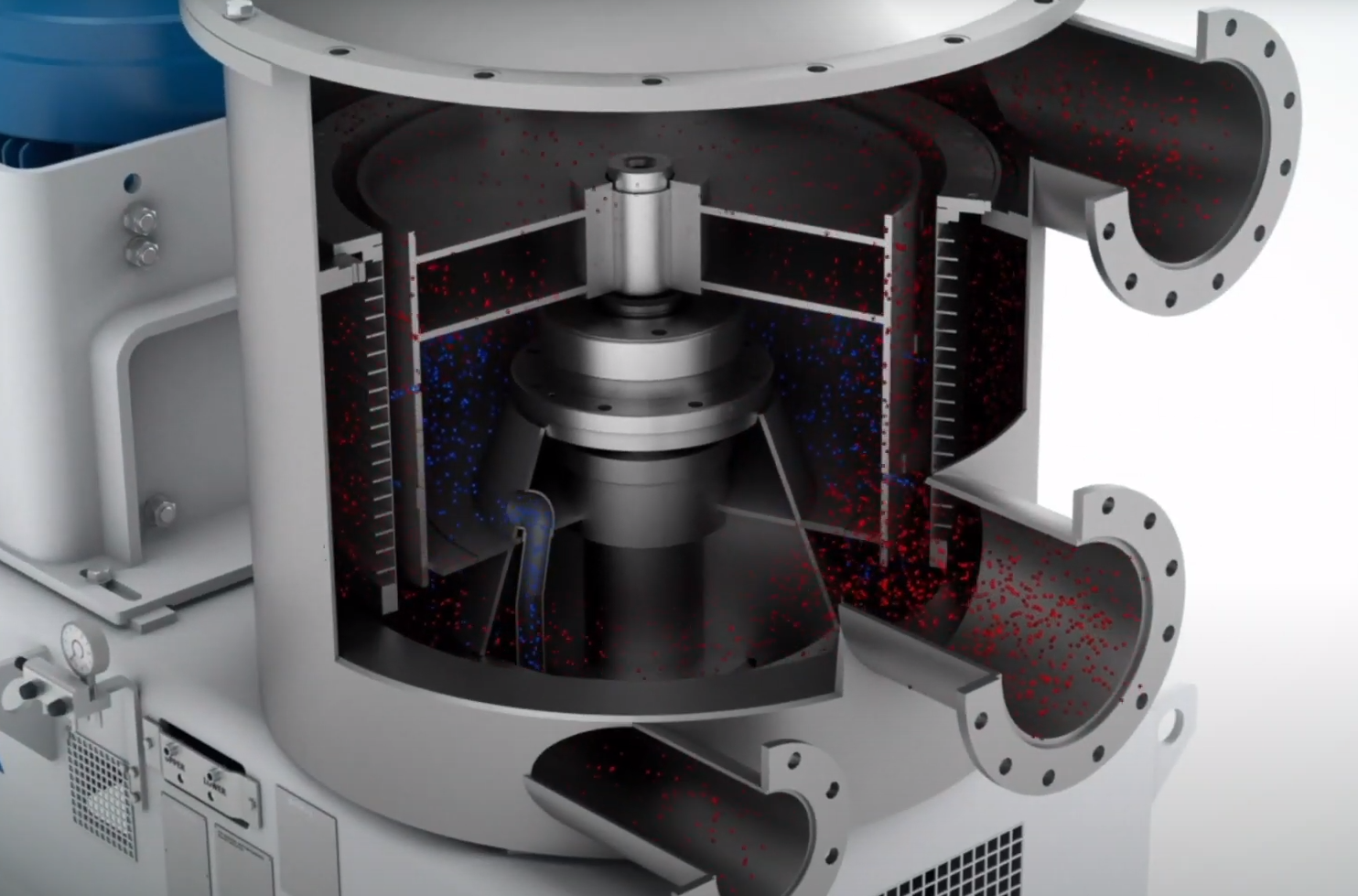

ANDRITZ has developed a dilution upgrade to reduce the reject thickening and at the same time protect the rotor interior from contaminants

ANDRITZ Dilution Water Upgrade

The three screens used for the bottom ply are a competitor unit in the first stage, an ANDRITZ ModuScreeen F30 in stage two. In stage 3 the tail screen involved in this upgrade is an ANDRITZ ModuScreen F20. The inspections revealed that as the stock was moving down the screen basket of the ModuScreen F20, it was becoming too thick (high consistency), causing too much of the stock to be discharged. As Ulf Scott explains, “There were big fibre losses from the dewatering and thickening. When the stock is too thick, it’s harder for it to go through the screen slots and what doesn’t go through ends up as rejects.” This was all despite the stock being screened multiple times via the system’s cascade design, where stock accepted from the second stage is fed back into the first stage and accept from the third stage goes back into the second stage.

In addition to the loss of valuable fibres and the cost of disposing of them, the too-thick stock consistency was also causing unnecessary damage to the stock-prep system itself. As Orban explains, “When the suspension is too thick, it can cause screen plugging, higher wear and it can even lead to unplanned shutdowns”. In this case, it wasn’t as bad as that, but even so, “The rotor was worn.”

Still, the main problem was the inefficient screening, with so much fibre being lost, and ANDRITZ’s solution was to reduce the thickness of the stock by introducing dilution water. That was done using the ANDRITZ Dilution Water Upgrade. Orban says, “This dilution water upgrade will improve most screening systems. It’s now successfully in use at Trebsen and several other mills, producing a wide range of paper grades, from newsprint to packaging.”

At Trebsen, the Dilution Water Upgrade involved installing a new housing for the bearing unit, while the rotor was fitted with new “Dolphin” foils, which agitate the stock efficiently, as well as minimising energy consumption. But the key part was the dilution water, which is now fed inside the rotor from below, through two new feed pipes, and then shot out through newly-drilled holes in the rotor, into the stock between rotor and basket. A new sealing ring maintains overpressure, keeps the dilution water where it is needed, and the turbulence of the rotor mixes it with the stock.

In this case, ANDRITZ removed the tail screen’s rotor and upgraded it, while Trebsen continued operating with spare equipment. ANDRITZ then put the finishing touches to the upgrade at the mill itself, culminating in installation during the mill’s planned maintenance downtime last year. The upgraded line then started up in June 2020. After trying out various adjustments volumes have now settled at 450 litres of dilution water per minute, which results in a reduction of the reject thickening by approximately 50%.

Results delivered – reduced costs, improved efficiency.

The result of the upgrade has been a reduction of about one third in fine reject volumes, contributing to a -25% to -30% drop in fine reject costs.

Results like these are not so obvious, the way the fibre market is going today. As any producer of recycled paper around the world will tell you, the quality of the available secondary fibre is getting worse all the time – which means more dirt in the raw material. In this context, Orban explains, “The goal was to have more useable fibres pass through the screen, while at the same time preventing dirt from getting into the system, which would reduce the quality of the stock. We want the fibres, not dirt. Several months of measurements and laboratory tests have shown that there has been no drop in quality.”

And in addition to that, “It’s a good environmental success for Julius Schulte,” says Orban. As Petrich points out, “That’s 1,000 tonnes of rejects no longer being transported on German roads – equivalent to around 40 trucks. And 1,000 tonnes less raw materials being transported in.”

Saving time and money

Orban said, “We got it done in the shortest time. Nowadays, no-one wants to talk about a project if the return on investment is a year, or even 6 months.” In this case, the investment has already paid for itself, with considerable profit. As Petrich says, “We were throwing away 1,000 tonnes of fibre a year. Now we’re using it.“

Petrich was more interested in the benefit to production, not only the cost: “We are a medium-sized company – we look at things on the long run, the solution must work and give us an advantage.”

But also a fast return on investment is important to us. And those advantages are big gains in fibre use, as well as less wear on the tail screen, due to reduced stock thickening (and therefore theoretically less maintenance and replacement parts used). As Orban explains, “The Dilution Water Upgrade also prevents build-up of debris under the rotor, therefore the wear in this area is now reduced. That means fewer repairs and longer operating times. The upgrade also protects the bearing unit.”

Petrich is also keen to mention the time it has saved him. “I used to spend much time taking care of the screen, but now I don’t need to. The best machine in the mill is the one where you have to ask yourself where it is, because it never causes any problems. This is not super-complex technology, but it was a fine project; a smart piece of work. We’re very satisfied with ANDRITZ.”

ANDRITZ ModuScreen F20 upgraded with the ANDRITZ Dilution Rotor Upgrade