Reduction of CO₂ with different decarbonization technologies.

Cement industry

Our customized process solutions for high-grade alternative fuels and carbon capture help to reduce the cement industry’s CO2 emissions

Cement is not only the backbone of the construction sector, but also a main contributor to the global CO2 emissions. We are supporting the endeavors for a more sustainable cement production for customers such as Schwenk and Rohrdorfer Zement, on multiple paths and with great success.

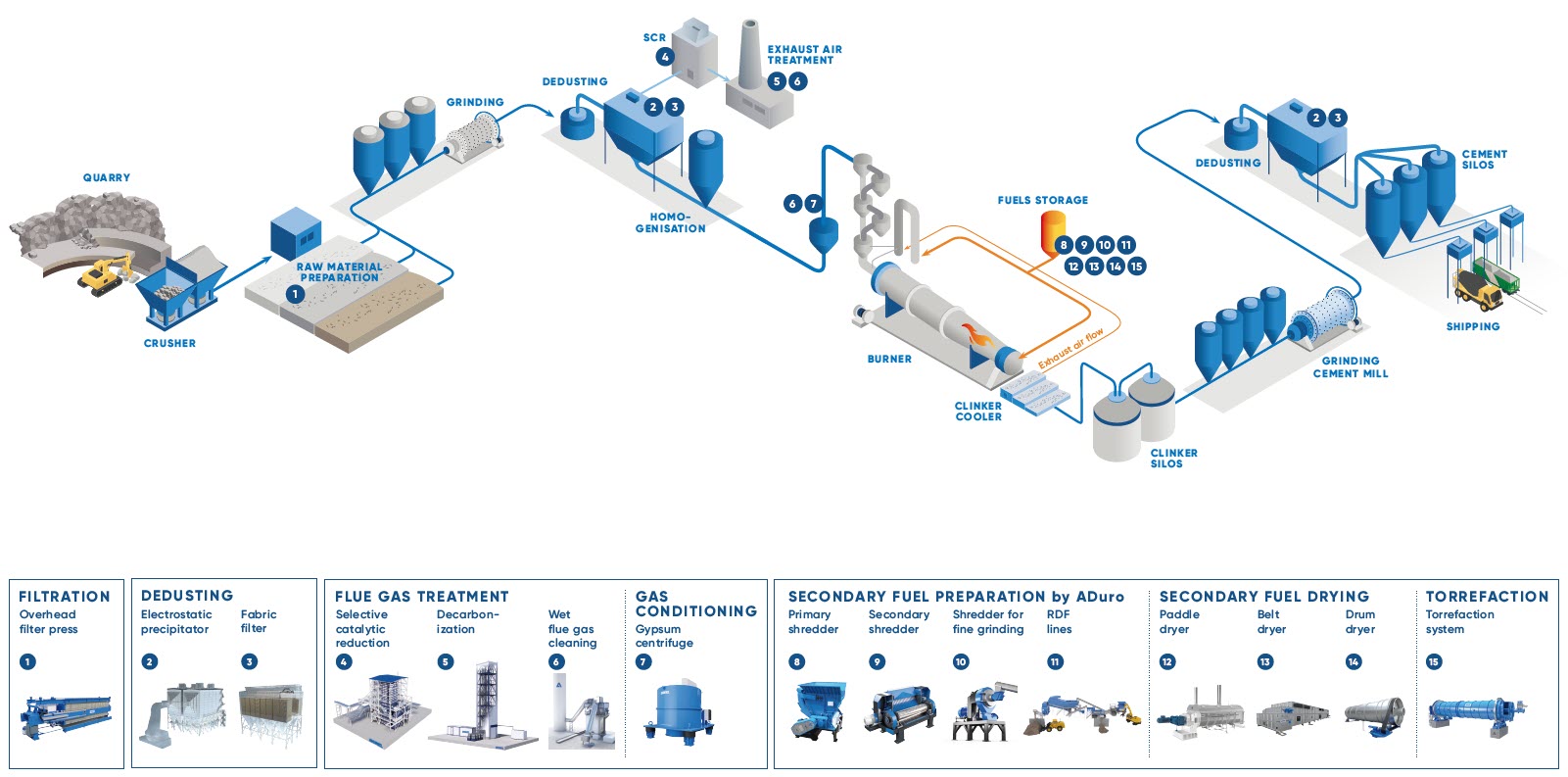

Where we fit into your process - based on the example of the clinker process

To help with cementing sustainability, we provide solutions for:

- raw material preparation

- dedusting and air filtration

- secondary fuel preparation

- CO2 capture and CO2 reduction

- NOx reduction

- SO2 reduction and scrubbing

- lab testing and R&D

To help with cementing sustainability, we also provide:

Denitrification: NOx reduction

Reduction of NOx emissions with Selective Catalytic Reduction (SCR).

Desulphurization: SO₂ reduction

Maximized SO₂ and dust removal.

Sustainable fuels: RDF and SRF pelleting

Reduction of emissions by substituting fossil fuels with RDF (Refuse Derived Fuel) or solid recovered fuels (SRF).

Sustainable fuels: RDF production plants

Reduction of emissions by substituting fossil fuels with RDF (Refuse Derived Fuel).

Zero liquid discharge

Reuse of process water for further cementing sustainability with a zero waste approach.

Automation, lime and cement

Helping to achieve operational readiness.