Do you have questions? Get in contact with us!

In many of the world’s most important industries, separation is vital to sustainable growth.

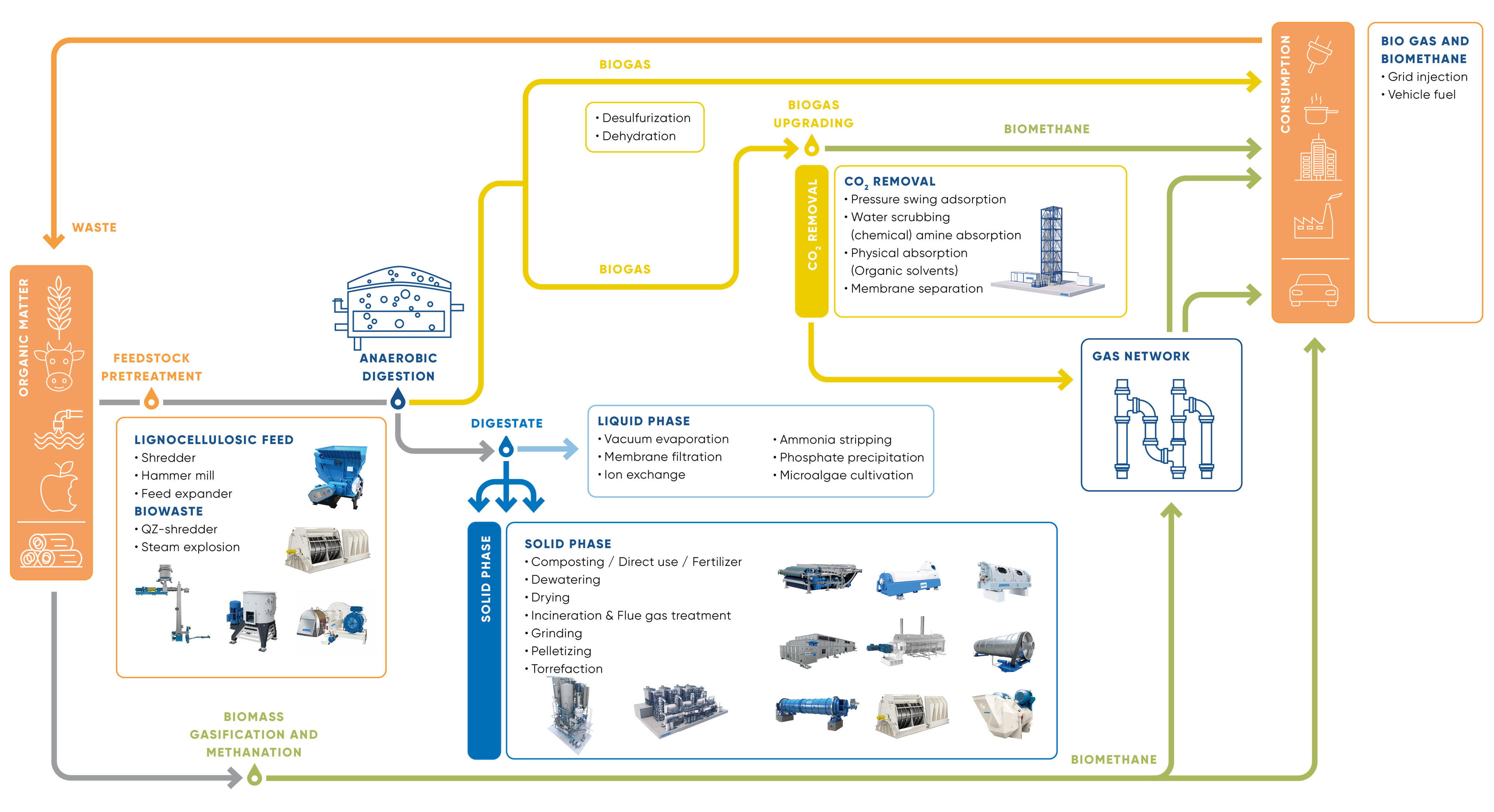

Biomethanization is gaining popularity, as it combines environmentally friendly properties with economic advantages. But the handling of the digestate after the extraction of the valuable biogas has a huge effect on the economic feasibility of such projects – as there is a high risk in wasting resources. ANDRITZ helps here with know-how in analysis, testing and process optimization – and, of course, with the right digestate dewatering and drying tools needed to be able to fulfill the great promise of the "circular economy".

Do you have questions? Get in contact with us!

With a wide range of dewatering systems on the market, selecting the right solution for your biogas extraction process is a tricky task. The waste fed before anaerobic digestion varies greatly and, therefore, the digestate does also. The challenge lies not only in the choice of dewatering tool, but also in predicting its performance level to optimize the equipment for the actual application.

With its vast experience in this emerging sector, ANDRITZ examines every stage of the operating process, checks the origin of the organic waste to categorize the slurry, and offers the right dewatering solution for your performance target.

What's more, with this solution you can be sure that no polymer, energy or process water is wasted, guaranteeing a truly green process.

Our offer: Unmatched process know-how, the right technologies and a strong commitment to sustainability

ANDRITZ combines comprehensive process know-how and decades of experience in municipal and industrial sludge treatment under one roof. Our portfolio covers various dewatering tools to treat almost all types of biogas digestate. From decanter centrifuges with specific abrasion-resistant properties to screw presses in a large variety of sizes and alternatives such as belt presses. All this is supported by our extensive know-how in process analysis, equipment selection, dimensioning, process optimization and smart automation solutions to use resources such as wash water and polymers as economically as possible.

An outstanding example of our expertise is the Laogang project, one of China’s largest bio-refineries. It recycles large amounts of Shanghai’s restaurant and kitchen waste from the central urban area by processing more than many tons of wet waste daily, 24/7, to produce biogas and biodiesel.

19 ANDRITZ decanter centrifuges D5LX are at the heart of this process, and the separation performance has even exceeded the customer’s expectations.