RDF is tailored for utilization as fuel in waste-to-energy facilities or industrial applications. It typically comprises combustible fractions like plastics, paper, and biomass, refined to meet stringent standards for calorific value, moisture content, and particle size distribution.

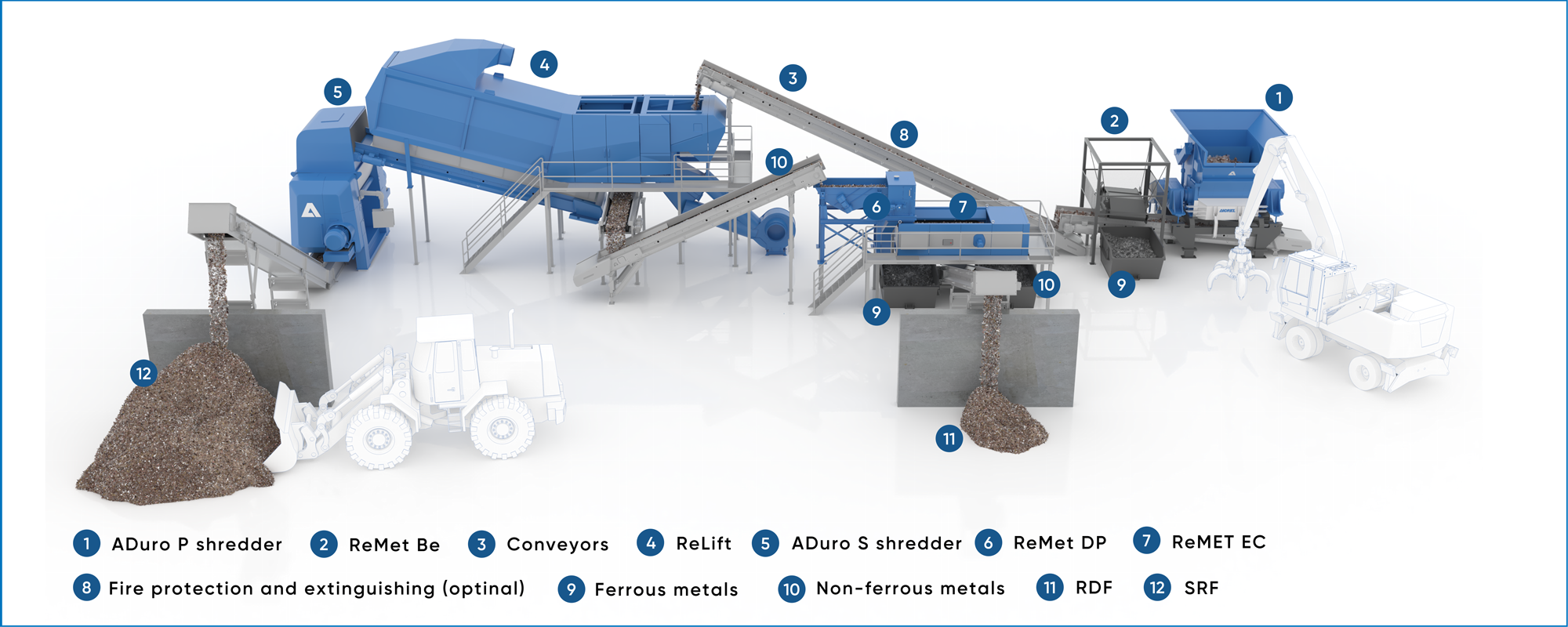

The robust ADuro P and ADuro S shredders are used for primary and secondary shredding. Quickly exchangeable screens allow many different output sizes. In the end, the ferrous metals and non-ferrous metals can be recovered with a superior purity of 98% – perfect for use in the steel industry.