ANDRITZ Metals Germany GmbH

Rolling Mills

The Sundwig 20-high cold rolling mill for production of the widest stainless steel precision strip as well as widest strip made of high-strength carbon steel, copper, copper alloys, and special materials in perfect quality

The history of the Sundwig 20-high rolling mill begins in the first half of the last century, when Sundwig (now ANDRITZ Metals Germany) developed a multi-roll cold rolling mill in 1930. Just a few years later, the first alligator-type 20-high rolling mill was built, followed in 1958 by the first 20-high rolling mill in Sundwig Four Column (SFC) design. Since then, ANDRITZ Metals Germany has continued to develop 20-high rolling mill technology consistently and ranks among the leading manufacturers in this field.

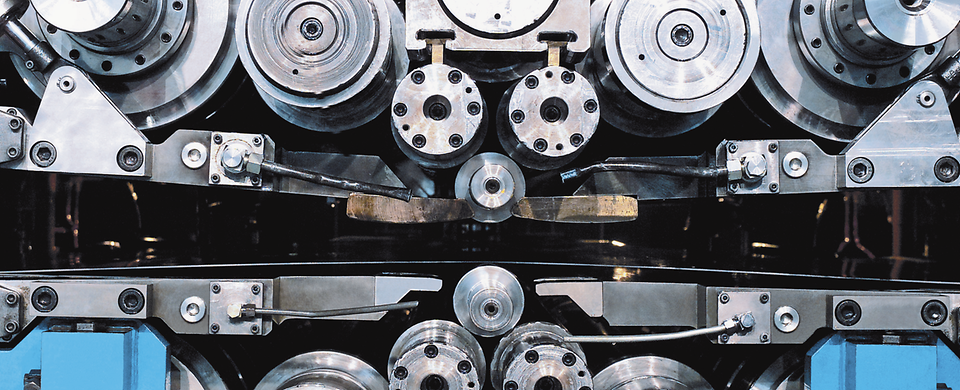

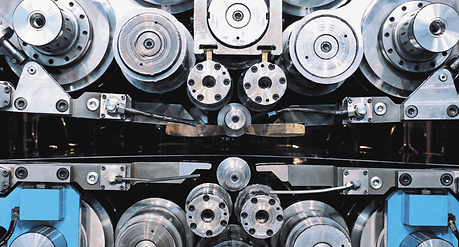

Today, ANDRITZ Metals Germany has numerous own patents for this technology and design, underlining the company’s focus on customer-oriented solutions. The axial shifting system (push-push), the impingement jet cooling system, and the rectangular back-up saddle design, for instance, offer distinct economic advantages.

The rolling mill stand houses all of the state-of-the-art flatness adjustment elements, like tilting, bending and axial shifting. The high-impact strip drying system ensures a safe rolling process up to the maximum rolling speed.

The fully automatic roll change by robot has substantially shortened rolling mill set-up times and, even more importantly, permits contact-free roll changing within a very short time without damaging the rolls.

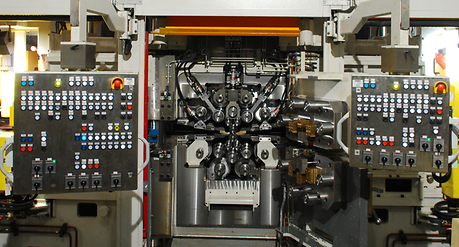

Outside the stand, the entire rolling technology is based on Sundwig’s experience, like the advanced safety concepts, modern fume exhaust system, rolling oil filtration, and the hydraulic equipment.

ANDRITZ Metals Germany’s many years of experience with AGC and shape control as well as the advanced mathematical process model and process optimization system secure highest product quality and operating reliability.

With more than 135 references for 20-high cold rolling mills, Sundwig is one of the most notable suppliers in this rolling mill technology segment.

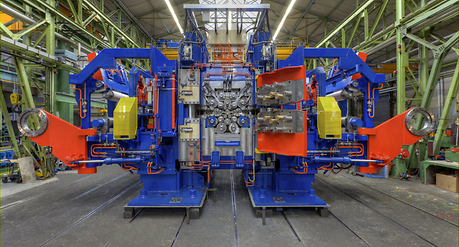

General view 20-high rolling mill SFC 300x1370 incl. tables for titanium and stainless steel

20-high rolling mill

20-high copper rolling mill SFC 220 x 650 mm for a Chinese customer