Optimization, data analysis, augmented reality

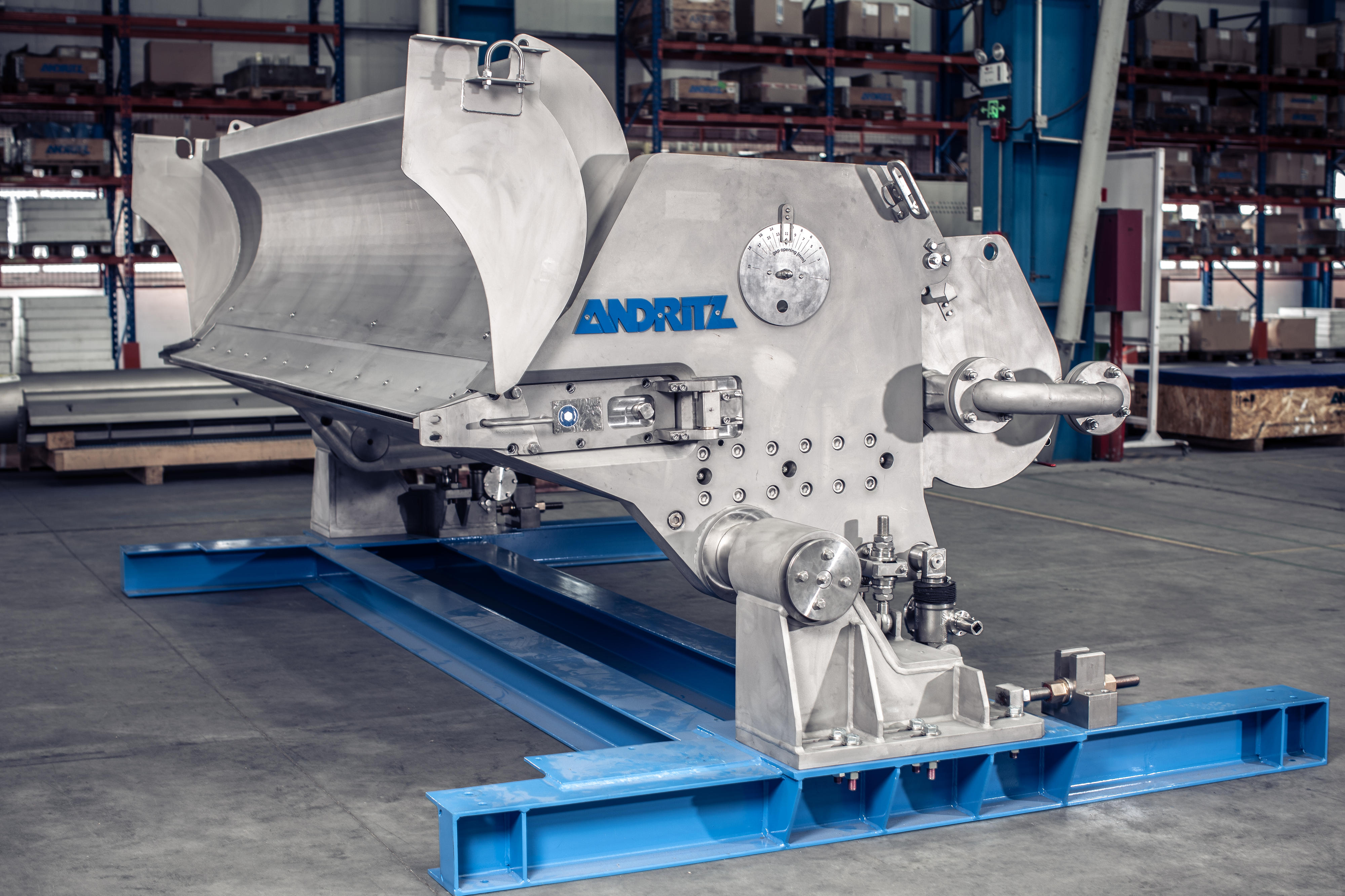

PrimeFlow headbox for tissue machines

The ANDRITZ PrimeFlow headbox for tissue machines features a unique eccentric shaft for slice adjustment that ensures minimized slice deflection. This enables best cross profiles even at speeds exceeding 2000 m/min. In addition, the step diffusor turbulence generator yields superior paper quality.

Design features

With the high headbox pressures in today’s high-speed tissue machines, tremendous slice rigidity is required to fulfil the cross-profile demands. The compact mechanical design of the PrimeFlow headbox family, with its unique eccentric shaft for slice adjustment, ensures minimal slice deflection.

- The step diffusor turbulence generator in combination with the optimized nozzle geometry yields superior paper quality.

- Easy and on-the-run adjustment of the jet impingement for optimum sheet formation.

- The overall design of the PrimeFlow headbox considers the operator’s needs for safe handling, cleaning, and maintenance.

Efficient turbulence generation

The optimized step diffusor comprises tube bundles with inserts for optimal formation over a wide range of headbox flow rates and consistencies. It creates streak-free paper, whilst the slim nozzle design provides a stable jet.

The well-proven PrimeProfiler F consistency profiling system ensures the best possible basis weight profile. All major components in the system are made of stainless steel.

PrimeFlow headbox

Multilayer technology

Multilayer headboxes offer the opportunity to efficiently use raw materials that fulfil consumer demands such as handfeel and strength. An internal lamella separates the individual flow streams in the nozzle, to generate a high degree of layer purity. The lamella is made of a high-performance synthetic material for durability and long life.

The PrimeFlow multilayer headbox is available with two or three layers for different applications in PrimeLine TM, PrimeLineTAD or PrimeLineTEX machines

At a glance

- Best cross-profile quality through structural rigidity, mechanical micro-adjustment, and consistency profiling system

- Easy on-the-run adjustment of the jet impingement, ensuring a high formation quality of a wide range of products

- Energy-saving design (low headbox circulation flow and higher consistencies) without compromising on product quality