1 machine, various configurations, vertical CrescentFormer option, shoe press, steel Yankee, TAD drums. Trials and trainings for tissue producers, pulp producers, suppliers to the tissue industry, converters, and R&D institutes.

PrimeLine tissue machines

PrimeLine tissue machines by ANDRITZ: Flexible and reliable tissue machines that incorporate both experience and innovation.

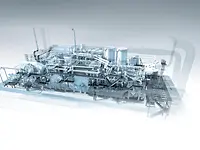

From complete tissue production lines down to single components, ANDRITZ delivers state-of-the-art tissue technology as well as air and energy systems. In addition, the ANDRITZ “Tissue Innovation and Application Center” comprises a complete, state-of-the-art tissue pilot plant, including laboratory facilities for tests and trials. It is available to tissue producers and suppliers, research and development companies, and universities.

Experts in tissue

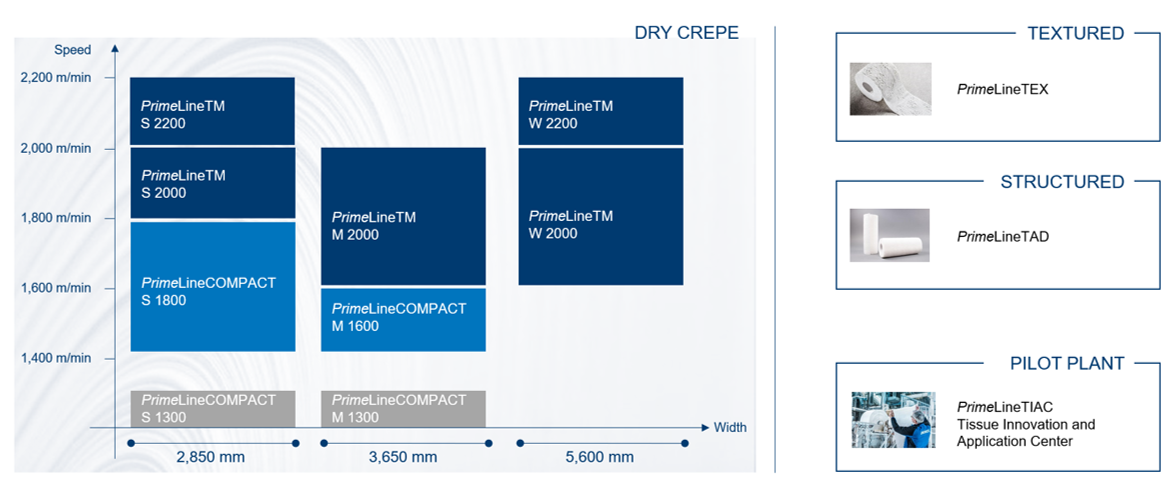

ANDRITZ PULP & PAPER is an experienced and proven partner to the global tissue industry. Through continuous development and project experience around the globe, ANDRITZ offers world-class tissue machinery and components with innovative features. Production speeds of up to 2,200 m/min, high quality paper grades (dry-crepe, textured, structured), as well as advanced solutions to reduce overall energy consumption form the basis of our offerings.

ANDRITZ tissue machines overview

There is increasing pressure for tissue producers to improve efficiencies and reduce consumption of energy. ANDRITZ has solutions which are innovative, efficient, and minimize the consumption of resources – without compromising product quality. PrimeLine tissue machines are available as PrimeLineCOMPACT, PrimeLineTM, PrimeLineTEX, and PrimeLineTAD tissue machines. Key components of these tissue machines are ideal for rebuilds and modernization projects.

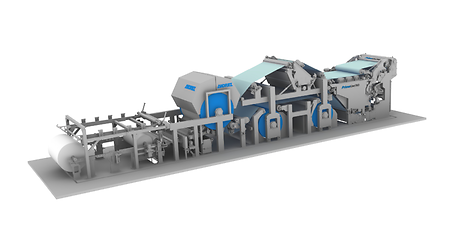

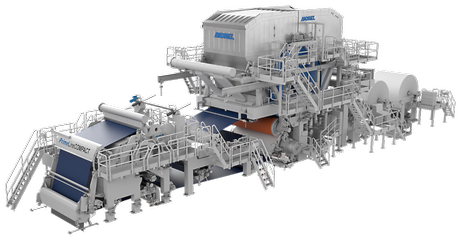

PrimeLineCOMPACT tissue machine

Standardization for a shorter payback and improved ROI

Choose one of four COMPACT tissue production lines based upon capacity requirements. With the PrimeLineCOMPACT tissue plant concept, ANDRITZ can deliver a full tissue-making system, from the stock preparation to the parent roll, including automation. To meet different customer requirements, four types of COMPACT concepts are available, representing different production capacities. The high degree of standardization of the concepts leads to a much shorter payback time and to an improved ROI.

PrimeLine COMPACT tissue machine

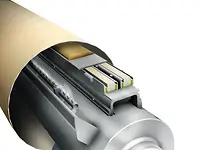

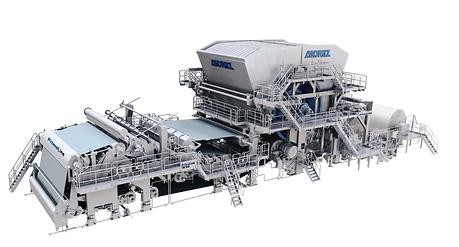

PrimeLineTM tissue machine

With key components that save resources

PrimeLineTM machines are widely embraced by the global tissue industry — not only because of proven performance, but also for continuous innovations. ANDRITZ brings new energy-saving features and capabilities to its CrescentFormer machines and components: Type S machines (widths from 2.6 to 2.85 m), type M machines (widths from 3.4 to 3.65 m), and type W machines (widths from 5.4 to 5.6 m), can be equipped with a shoe press, a steel Yankee (up to 26 ft. diameter), a steam-heated Yankee hood and a steam generator, which help to improve yield, efficiencies, and energy conservation.

PrimeLineTM

PrimeLineTEX tissue machine

High-end product quality at lower costs.

The new ANDRITZ machine PrimeLineTEX enables customers to produce textured tissue of a quality being superior to dry crepe and very close to structured (TAD) tissue, while at the same time achieving significant cost savings.

PrimeLineTEX is available with widths of 5.6 or 2.8 m and produces high quality tissue for towel and sanitary applications. The machine offers up to 25% fiber savings compared to dry-crepe and even 50% less energy consumption compared to TAD. The machine is remarkably shorter in length than other market solutions, and uses only one additional fabric instead of two. Furthermore, the PrimeLineTEX machine can swing between textured and dry-crepe tissue within much shorter time than comparable solutions.

PrimeLineTAD tissue machine

Premium tissue through-air drying technology

The improved softness, absorbency, and bulk generated by the Through-Air Drying (TAD) process give these products superiority over conventional processes.

Find out more about our tissue technologies...