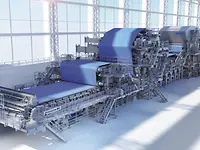

With diameters up to 26 ft. and shell lengths up to 8.4 m, ANDRITZ is the technology leader for large steel Yankees

PrimeDry technologies for tissue

ANDRITZ PrimeDry technologies for tissue machines aim at improving drying-efficiency and energy savings. Steel Yankees, air and energy systems as well as mist and dust removal systems and hall ventilation equipment are part of our product range.

Our drying solutions for tissue machines include high-temperature hoods, re-evaporation heat recovery systems, and wet dust removal systems. They improve tissue drying rates at very low costs.

PrimeDry HotAir Box

In tissue production, drying capacity and machine speed are often constrained by the fundamental limitations of water removal—particularly due to water’s viscosity restricting the efficiency of suction rolls. This has historically been a major roadblock for increasing production efficiency.

The PrimeDry HotAir Box focuses on utilizing exhaust heat to enhance energy efficiency and reduce carbon dioxide emissions in tissue-making processes. Designed for both new installations and upgrades, this innovative technology significantly enhances drying capacity and enables higher machine speeds, unlocking new levels of performance for tissue production.

Read the full interview with Luca Linari, Managing Director of ANDRITZ Novimpianti.

PrimeDry HotAir Box Close up

PrimeDry HotAir Box: Highlighted air systems

PrimeDry HotAir Box with air systems