Innovation for efficiency

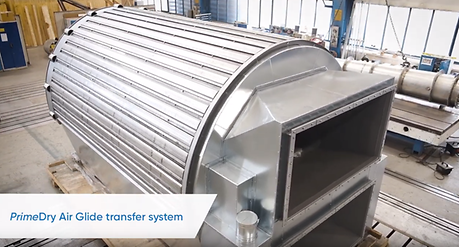

To improve efficiency, the fabric run is designed without outer fabric rolls. Another increase in efficiency comes with the fabric cleaning technology and the device for CD moisture control that can avoid the over-drying of the paper. The dryer section is ventilated by blow doctors and/or other ventilation equipment. A ropeless tail threader (PrimeFeeder) can be used in single and/or double-tier configurations.

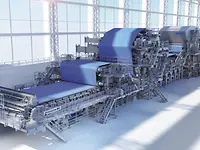

For drying sections of all kinds of paper machines we offer different hood solutions, heat recovery, steam and condensate systems, web stabilization systems, MG Yankees and drying cylinders.