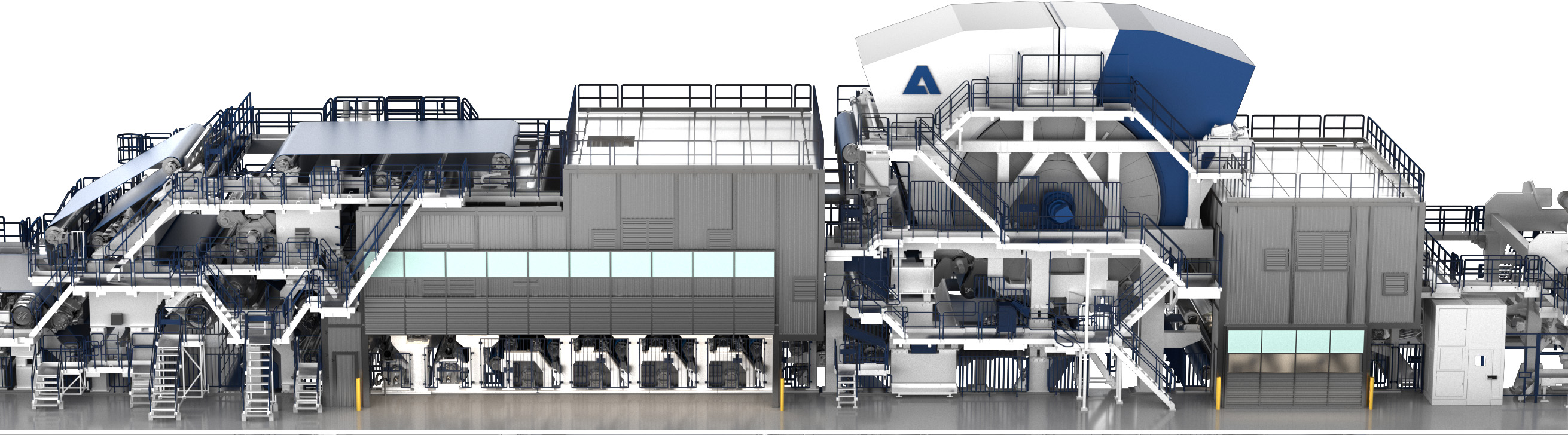

PrimeDry Hood C

CLOSED PAPER MACHINE HOOD

The PrimeDry Hood C encloses the pre- and postdryer sections with insulated panel elements down

to the machine floor level. Cold air is prevented from entering the drying section by the basement enclosure, which creates a virtually closed hot area inside the paper machine hall. There are lifting gates on the operator side so that free access is available to the dryer section.

The hood keeps heat losses in the dryer section low, prevents condensation, and prevents room air from entering. As a result, the temperature and humidity throughout the machine hall are improved.