About the project

The four tissue machines are of the type PrimeLineTM W 2000, with a design speed of 2,100 m/min and a working width of 5.68 m. They are equipped with fully cantilevered shoe presses for gentle dewatering and easy maintenance and 18 ft. steel Yankees with steam-heated hoods for energy-efficient drying.

The new tissue mill will be self-sufficient in steam and electricity consumption for the drying process, making it one of the tissue mills with the smallest CO2 footprint in the world.

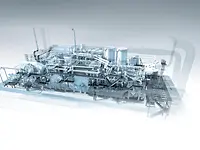

ANDRITZ’s scope of supply – on a turn-key basis including civil construction – includes the stock preparation systems that will process slush pulp from Bracell’s own pulp mill, rewinders and roll handling, as well as roll covers, machine clothing, shoe press belts, and additionally more than 100 units of high-efficiency process pumps.

All four plants will be equipped with the Metris X integrated distributed control system (DCS), which ensures optimal plant operation. The combination of advanced data analytics, automatic condition monitoring system with Metris Vibe, integrated high-end advanced process controllers (APCs), artificial machine intelligence (AI), the implementation of digital twins and operator training simulators (OTS) support the rapid commissioning and optimal operation of the plants throughout their life cycle. Assistance in maintenance processes completes the package.