Recovering high-quality lignin from black liquor in kraft mills.

ANDRITZ Lignin Recovery technology for kraft mills

The benefits to installing Lignin Recovery technology in a kraft mill include the ability to debottleneck a recovery boiler and the potential cost savings from substituting a sustainable biofuel for purchased fossil fuels. Lignin is also being utilized as a sustainable, renewable raw material for advanced bioproducts such as composites or as a substitute for phenolic and aromatic compounds, which might create an additional revenue stream for a kraft mill.

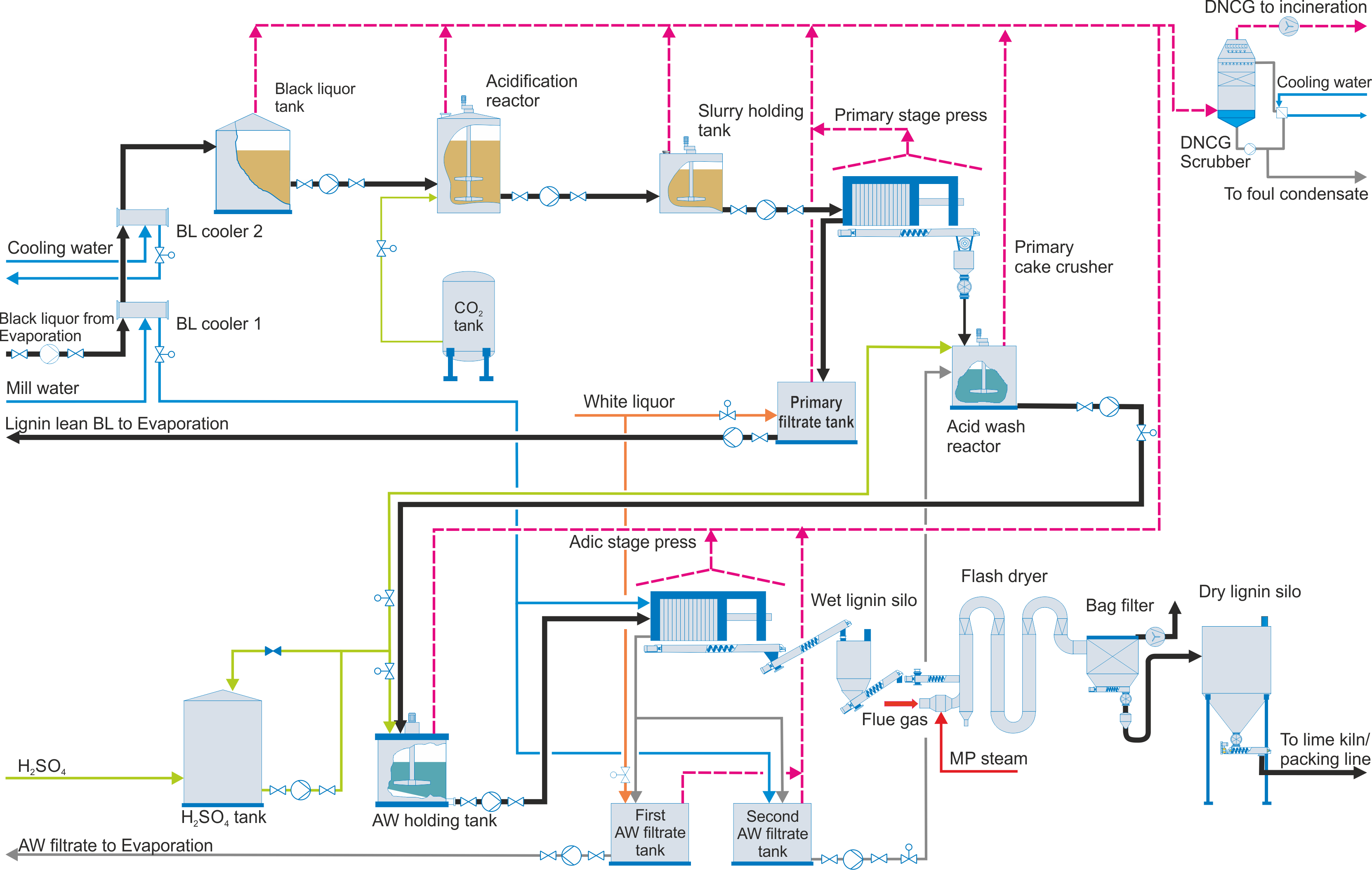

The ANDRITZ LignaRec lignin recovery process