Superior environmental performance

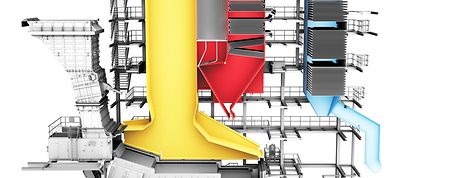

The removal of nitric oxides (NOx) and sulfur oxides (SOx) is easily accomplished with CFB combustion. PowerFluid boilers can meet strict emission requirements without adding post-combustion cleaning equipment, such as flue gas desulfurization and selective catalytic reduction systems.

The low temperatures and staged combustion in the furnace prevent thermal NOx formation and suppress the oxidation of fuel nitrogen – resulting in low NOx formation and high fuel burnout rates. Low cost limestone used as a sorbent in the furnace captures the fuel’s sulfur components in a simple and efficient way during the combustion process.