Especially consistant high product throughput, combined with purity, is critical to the required cost-efficient production of all types of battery minerals. This is why many larger processors of graphite, magnesium and cobalt have long depended on us for the most efficient mechanical dewatering and purification solutions.

- Lithium dehydration,

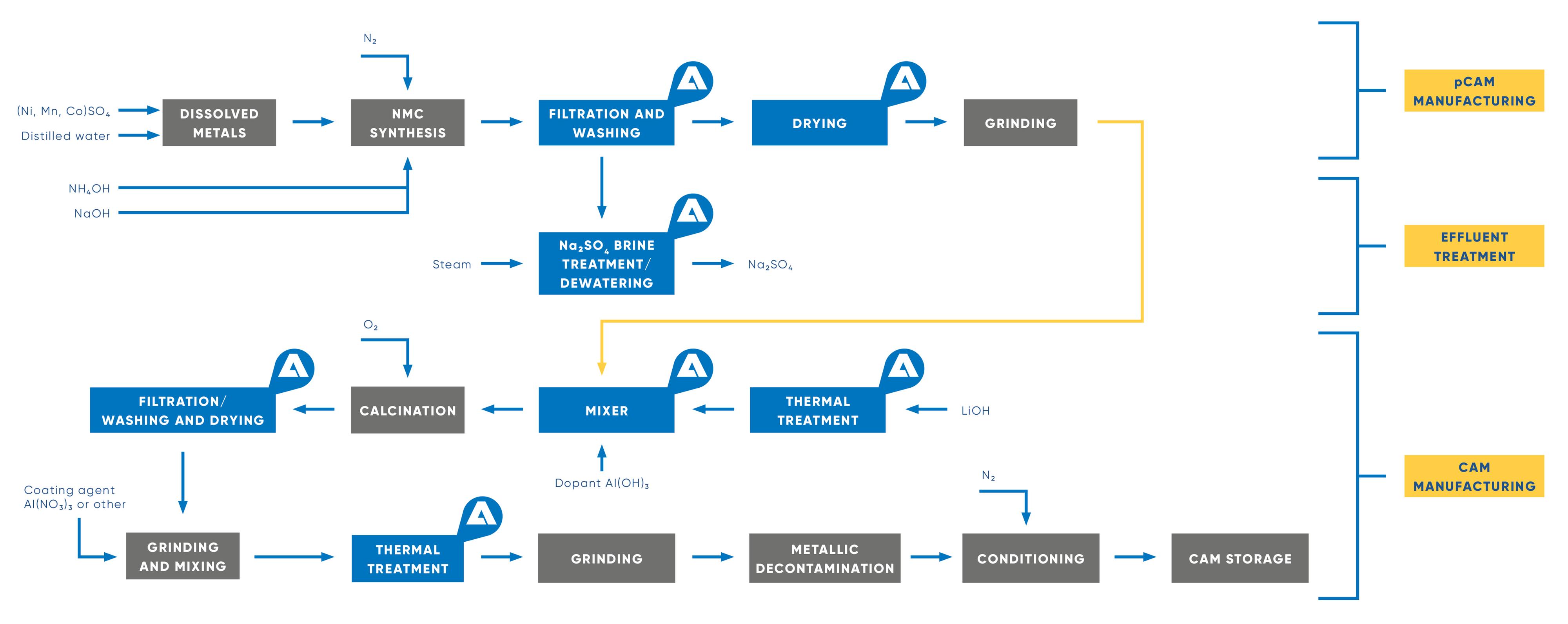

- precursor fine or middle particle filtration,

- precursor fine or middle particle drying,

- calcination filtration or pre-calcination cooling?

We’ve got you covered!