Metsä Group’s Äänekoski bioproduct mill has been the talk of the global pulp and paper industry for some time now with its outstanding environmental efficiencies and ambitions for new products derived from wood. Starting up in August 2017, ANDRITZ supplied crucial technology to help make the Äänekoski bioproduct mill a showcase production site for the 21st Century.

Going live

Videowall technology for pulp mills

Monitoring woodyard and fiberline operations at pulp mills just got a lot smarter with ANDRITZ Decision Support Walls.

In all aspects of our lives, we are becoming much more used to information being delivered on demand and with as much choice of visual effects and data display as possible. Information is King, and the clearer, more concise, and effectively illustrated, the better, as it all goes to helping us manage our time more efficiently.

The ANDRITZ Decision Support Wall (DSW) brings the latest in Industrial Internet of Things (IIoT) and smart technology right into the heart of the pulp mill control room for monitoring woodyard and fiberline operations. The DSW comprises a bank of screens delivering high definition (HD) quality live videos from processes and equipment, which can also provide live data recording and reporting facilities together with advanced alarm triggering, instantly highlighting any problems or potential problems.

THE TRAFFIC LIGHT SYSTEM

Along with the DSW, ANDRITZ is introducing a process diagnostics display with key performance indicator (KPI) values where process status is illustrated with colors and values that are controlled by the Metris tool rule base. The Traffic Light system is a new addition to help monitor and maintain the efficient running of the woodyard. When a green light is being displayed on the system, all is running well; when a yellow light appears, it means the operator needs to do something: for example, when monitoring the condition of knives in the chipper.

Essentially, the Traffic Light system alerts an operator to a problem before it becomes a major issue and therefore gives the opportunity for early action and is an excellent tool to assist in preventative maintenance.

For the woodyard there are detailed, HD video displays for ANDRITZ chipper and crusher equipment as they are running, along with Smart Woodyard products like ChipperEKG and CrusherEKG online process monitoring combined with advanced diagnostics. There are interactive tools for operations and maintenance, which can also include video transmitted from a helmet camera or smart glasses. Real-time information being fed back includes KPI calculations for availability, production, quality, and energy consumption.

The system can also “publish” data from any operator interfaces that includes information supporting operators in their daily job, like ANDRITZ WoodScan, BarkScan and ChipScanLT in the woodyard, as well as DD-Washers and K4000 chip level measurementin the fiberline.

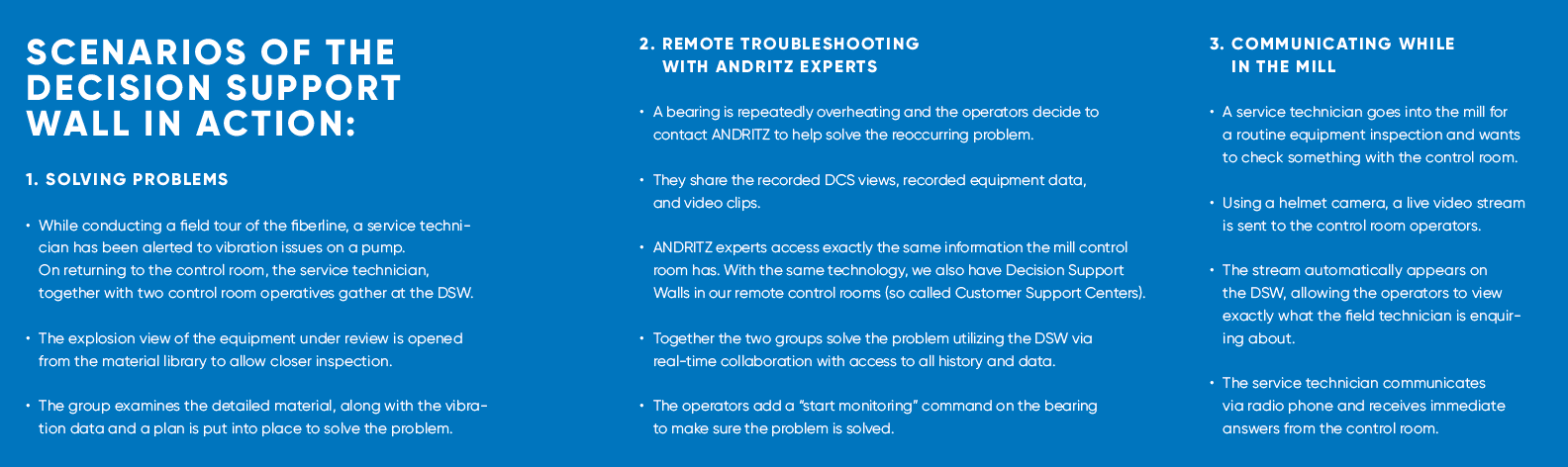

The DSW can be used for a variety of different purposes; for instance, selecting the “Morning Meeting” will enable all operators in the control room to have instant KPIs displayed, along with alarm statistics and a shift logbook allowing a view of any vital information at the click of a mouse or touch of a screen.

There can also be an instant Internet connection with the experts at ANDRITZ where any information can be shared and viewed for process optimization or problem solving purposes.