ANDRITZ has designed a broad range of high-consistency (HC) refiners to meet the demands of pulp, paper, panelboard, and recycle producers. At the top of the line in terms of throughput and motor power is the TX68 twin refiner.

TechNews: PrimeFilter D disc filter - Upgraded performance and reliability

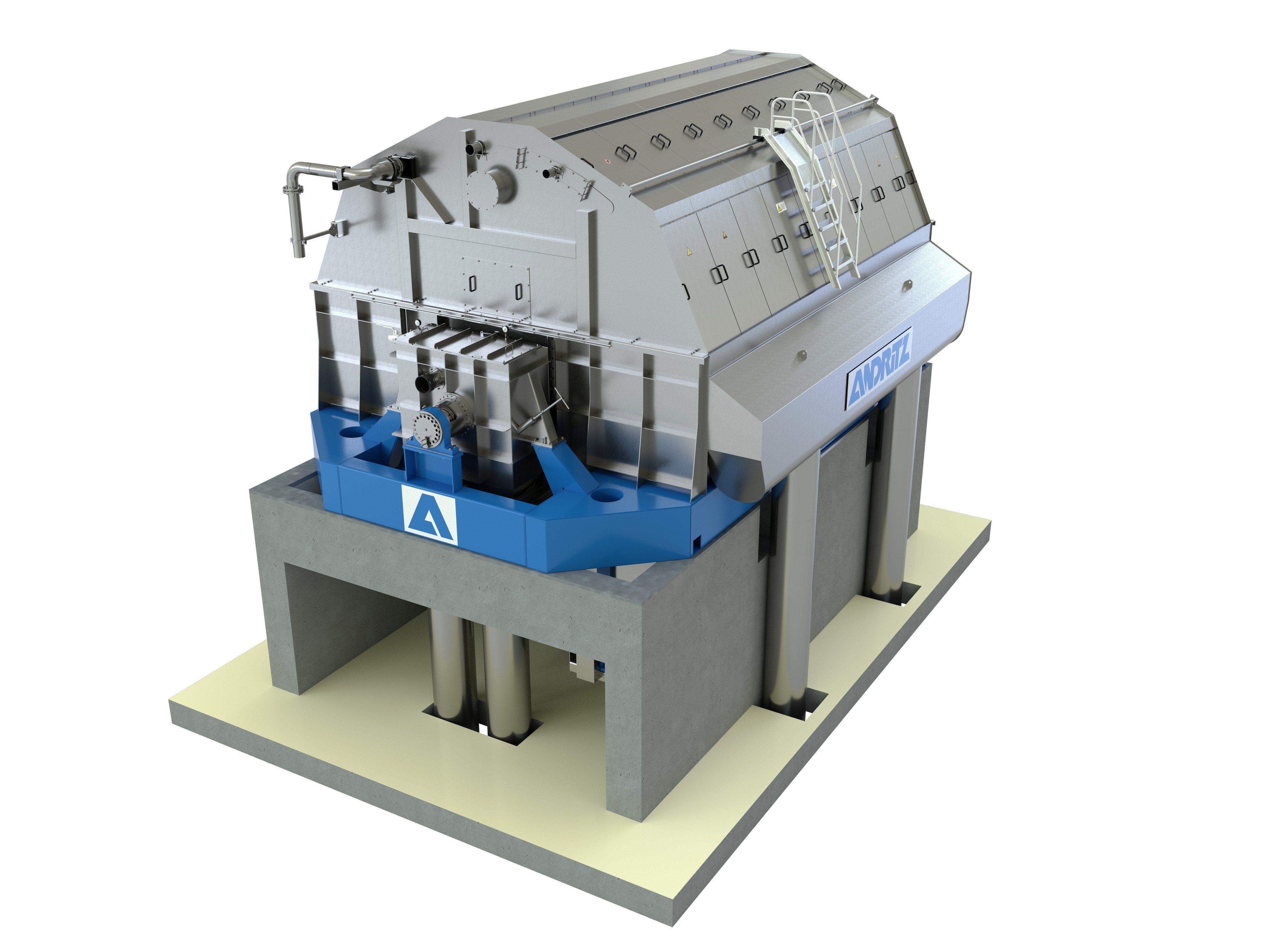

Major upgrades and a series of smaller innovations have been incorporated into the new ANDRITZ PrimeFilter D to improve performance and reduce maintenance. The new design includes the latest bagless technology, which is well-proven in over 65 installations to date. The upgraded PrimeFilter D has been well-received already – 15 units have been started up and more orders are being received from leading papermakers.

When engineering the new PrimeFilter D, ANDRITZ specialists evaluated the performance of over 600 disc filters the company has installed around the world, spoke with customers, and re-examined the design from end-to-end. The result is a disc filter that is perfectly suited for thickening all kinds of pulp and operating at higher consistencies, and for producing excellent quality filtrate when applied as a saveall for fiber recovery in PM white water systems.

New ANDRITZ PrimeFilter D

MAJOR UPGRADES TO TECHNOLOGY

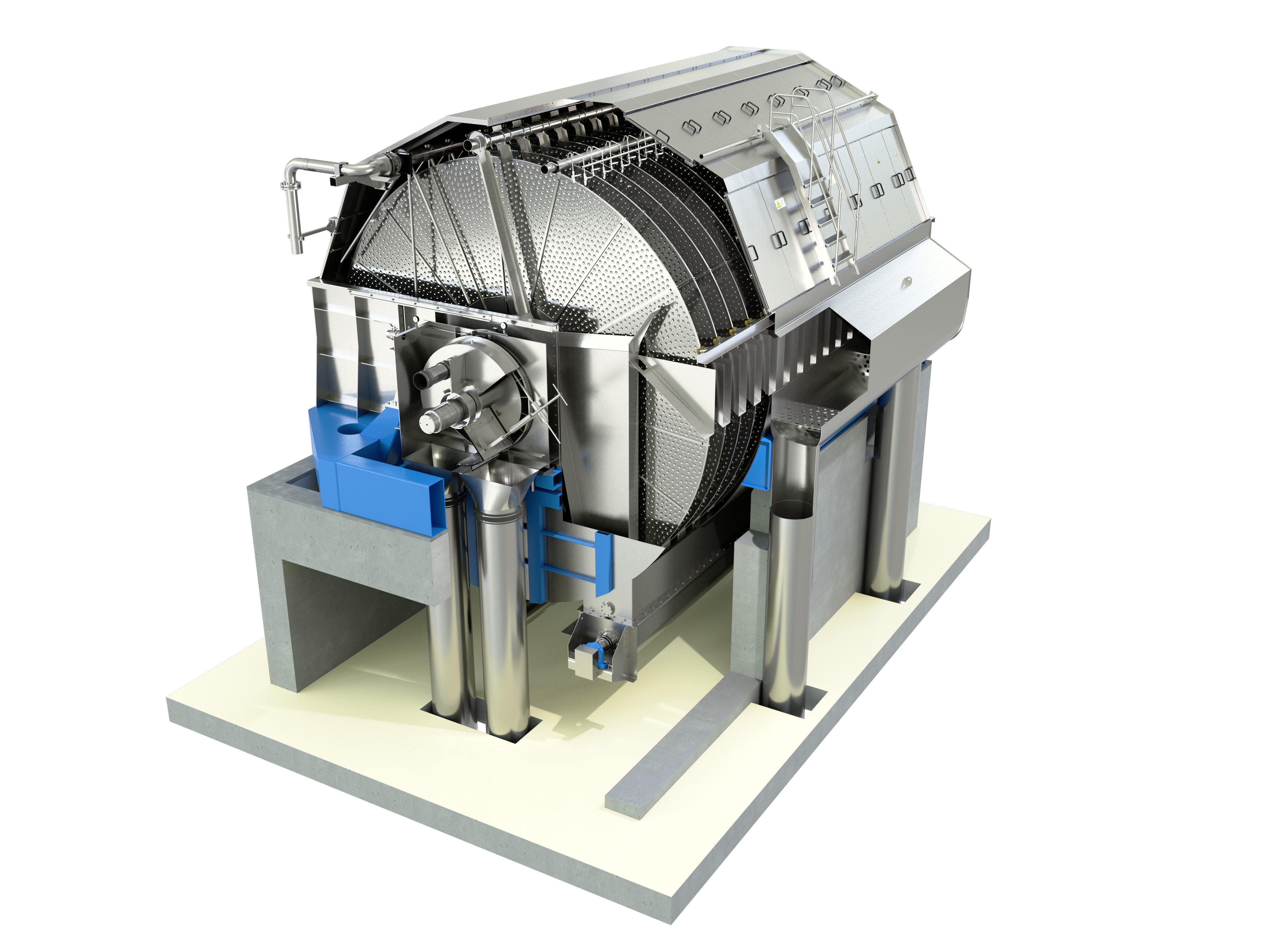

The PrimeFilter D fuses several key technological innovations into one unit to improve throughput and reduce both investment and operating costs.

HHw for even the most demanding thickening applications. HHw stands for High consistency, High freeness, and a wider distance between discs. This enables the PrimeFilter D to handle higher feed consistencies and higher freeness pulps.

Conical Cell bagless sectors for uniform fiber mats, long life, less maintenance. The Conical Cell bagless sector design of the PrimeFilter D (Figure 5) offers significant improvements in terms of operation and maintenance.

Two-level shaft sealing for improved reliability and filtrate quality. A significant technical improvement in the PrimeFilter D is its advanced double sealing arrangement. The sealing is outside the filtrate valve making it easy to access. This eliminates the possibility for fibers to enter the filtrate directly. Ease of access allows the seal to be exchanged without removing the filtrate valve housing, covers, and sealing support. In addition, no realignment of the filtrate valve is necessary after a seal exchange.

Advanced feed system for PrimeFilter D

A RANGE OF OTHER DESIGN IMPROVEMENTS

The PrimeFilter D has a simple, ruggedized system for installing and locking the disc sectors into place with guide bars at each end. Integrated into the base of each sector is a tapered positioning plate (Figure 8) that guides the sector into position in the shaft. A rugged rubber seal covers the sector foot flange to ensure sector-to-shaft sealing for stable vacuum and enhanced filtrate flow.

Knock-off nozzles have been redesigned to make it easy to flush out fibers and deposits. A simple hand lever engages the easy-cleaning function while the filter is in operation.

THE COMPLETE PACKAGE

The new PrimeFilter D delivers superior throughput and operation (Figure 9). The uplift in production can be a 30% gain per disc surface area. Inlet consistencies up to 2% are possible. Up to 30% less pumping energy is consumed due to less water in the suspension and reduced water recirculation requirements.

The fiber mat created on the Conical Cell bagless sectors is optimum in terms of formation and uniformity. The bagless sectors eliminate the need to shut down to change filter bags and the improved design for aligning and supporting disc sectors ensures overall smooth operation.