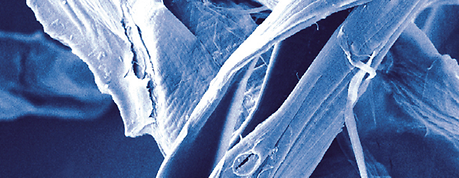

Advanced TMP (ATMP) – focus on energy savings and improved mechanical fibers

TechNews: High capacity high performance - TX68 refiner features new feed system

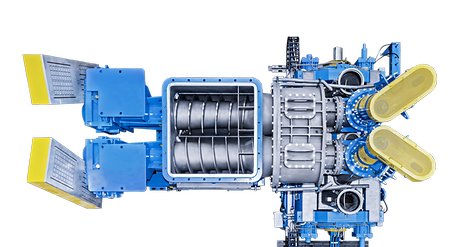

ANDRITZ has designed a broad range of high-consistency (HC) refiners to meet the demands of pulp, paper, panelboard, and recycle producers. At the top of the line in terms of throughput and motor power is the TX68 twin refiner.

Constant feed of incoming chips, which are split exactly on each side of the refiner

PRECISE, CONSTANT REFINING GAP

The TX68 is a twin refiner, combining two refining zones in one machine. It maintains a constant refining gap to ensure the best application of specific energy to the fiber while keeping pulp quality constant over time. This is due to a design that balances the forces on the disc and robust construction of both the rotating disc and the stators. The TX68 incorporates Zero Spin Deflection – centrifugal forces are 90° to refiner axis – a feature that eliminates the influence of negative rotor dynamics (such as an imbalance of deflection of the shaft) on plate parallelism and the refining gap. In addition, two-axes tramming allows adjustment to keep the rotating and stationary plates perfectly parallel.

The refining gap in the TX68 is amazingly precise for such a high-throughput machine. The gap is automatically adjusted with a fast and accurate plate adjustment system. A small and constant gap across the entire diameter of the disc produces less shives and better fiber quality. The position of the rotating disc is fixed and the stator position precisely defines the refining gap on each side of the TX68. Hydraulic cylinders on each end are servo-controlled to automatically adjust the gaps to allow fast loading and unloading in response to process fluctuations or operator entries.

Feeding system lifted for twin refiner opening

ADVANCED FEEDING TAKES TX68 TO HIGHER CAPACITIES

The TX68 has separate chip feeding for each refiner side, separate back steam outlets on each refiner side, and a common blow line for fiber and steam.

Although “new” in its current form, the advanced feeding system combines well-tested and proven concepts of ANDRITZ’s Side Entry Plug Feeder (SEPF) with a Constant Feeder (C-Feeder). The “new” development is that each side of the twin refiner has its own SEPF and C-Feeder.

The symmetrical split of feed material to each side of the TX68 is achieved by 100% filling of the feed screws. Throughput is determined by the speed of each screw and is controlled independently. The compression zone of the feed screw forms a dewatering area to eliminate free water and maintain a constant feed consistency.

EASE OF PLATE CHANGES

Two hydraulic systems are built into the TX68 to make plate changes easier and faster. One system lifts the feed system out of the way and the second opens the refiner casing. This provides direct, maintenance-friendly access to the refiner. A sliding flange at the inlet makes it simpler and faster to lift the unit.

PROVEN PERFORMER

The highest capacity TX68 operating today has a design throughput of 900 admt/d of eucalyptus pulp for the production of both board and printing and writing grades. There are other units, with capacities around 500 admt/d on newsprint and improved newsprint applications, with pine and spruce as the raw material, which require higher specific refining energies and therefore have lower capacities. The future trend is for even higher capacities up to 1,500 admt/d, which is well within the design capability of the TX68.