The project meant embarking on a task that had never been carried out before, in fact it was a world first. The scope included installing a Hydraulic Commander to provide more stable refiner load control as well as improved quality control. The installation also included the ANDRITZ refiner protection system, ADVACON. Also, a new plate positioning control system was installed on the refiner that permits control via a hydraulic servo valve without TDC sensors, which considerably improved response time, accuracy and efficient operation.

Sylvain Renaud, ANDRITZ Automation Product Manager, HC Refiners, says, “We first presented the Hydraulic Commander solution, along with ADVACON in 2018, and Clermont showed a keen interest in the automation it would bring to the refiner.

“At first the mill was going to use the existing TDC for controlling the plate gap, but it was subsequently decided to go with the ANDRITZ contactless position sensor.”

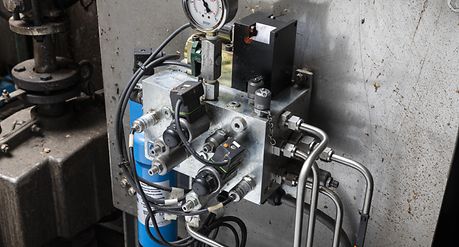

The complete plate positioning control system was installed on the CD70 refiner starting-up in March 2019 as planned, with the hydraulic conversion being completed in just four hours, and included removing the guide valve, connecting the new hydraulic block disconnecting the TDC sensors and verifying motor start-up sequences and logistics.

The new control system now manages simultaneous plate positioning of the CD and flat zone on the CD refiner. It maintains plate positioning on both zones using standard contactless sensors. The control system also manages plate protection, protection logistics static and dynamic zero, as well as providing an up-to-date control platform that is user friendly for operators.

Mill manager Bouchard is delighted with the results of the updated refiner, he says, “We have gone from monitoring the running of the refiner literally by the sound it makes, to now being able to actually analyze the data and fine tune the efficiency and quality of the output.