ANDRITZ Soutec AG, Switzerland

Rotfarb 4

8413 Neftenbach

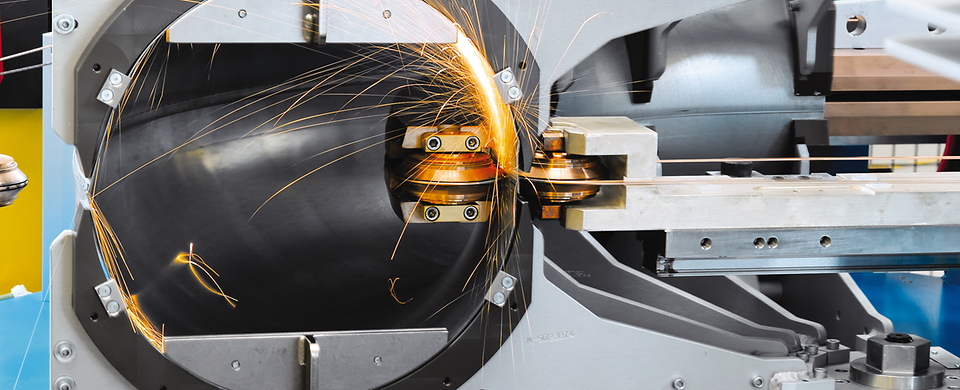

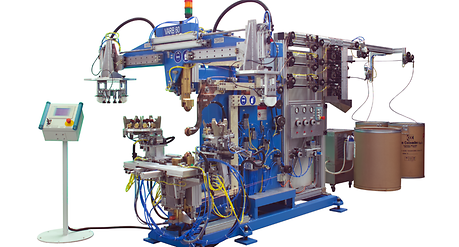

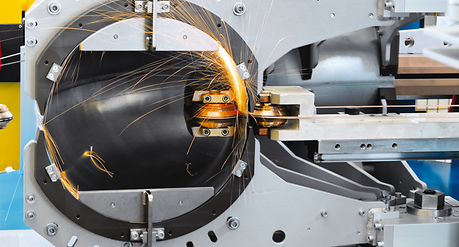

The VARB is a fully automated variant of the VSTW-RBi-RBa for elbow with a maximum diameter of 200 mm (8").

The VARB automated stitchwelder

Depending on the requirement, the pre-fabricated half shells can be placed into the tools manually or automatically by a robot. The weld operation is fully automatic and has consistent quality.

The VARB is best suited for applications with a high degree of automation and large production runs that need to be handled in a cost-efficient manner. The VARB requires a separate clamping and holding tool for each pipe bend diameter. No more than 10 minutes are normally needed for retooling, including time for changing of material and adjustment of parameters.

Dedicated tooling sets for each diameter

| Parameter | Value |

| Elbow diameter | min. 80 mm | 3.15” max. 200 mm | 8” |

| Material thickness | 0.3 – 0.9 mm | 0.012 – 0.035" |

| Overlap | variable |

| Copper wire | 2.0 mm round | 0.078" round |

| Weld speed | 2 – 9 m/min | 6.6 – 30 ft/min |