ANDRITZ Soutec AG, Switzerland

Rotfarb 4

8413 Neftenbach

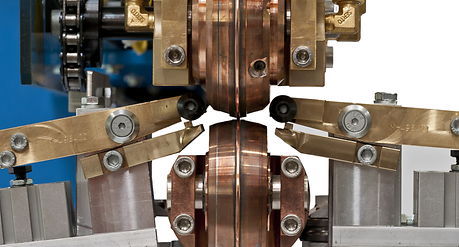

With roll seam welding, weld rolls assume the task of the electrode and the pressure tool.

A copper wire is guided between the rolls and the work piece while simultaneously providing a constant high quality weld seam. The copper wire allows for minimal wear to the weld rolls. Welding spots are set closely by the rolls to allow for a continuous leak proof seam. The pulse frequency of the current determines the spot weld spacing. For tack welding the spots are set further apart.

If a completely leak proof seam is required then the frequency is increased and a continuous seam is created. Movement can take place during the welding process between the work pieces and the roll electrodes as a result from the rotating electrodes in roll seam welding. This allows for the creation of a safe leak proof weld seam.

Deviations may occur when a work piece is moved and will not have a detrimental effect on the quality of the weld seam. In order to keep abrasion and wear on the expensive weld rolls at a minimum to ensure a constant high quality weld seam, we exclusively use roller heads with wire intermediate electrodes in our welding applications.

Weld rolls

| RFA | Automated annular flange welding machine |

| Beer keg casing welder | Automated beer keg chasing welding machine |

| RQB | Automated brake shoe welder |

| Contour II | Fuel tank welder |

| Inner beer keg welder | Automated inner beer keg welding machine |

| VSTW-R spez. (Schako) | Ventilation inlet vane welder |

| SWA 400 | The stitchwelder for high production runs |

| SWA 650 | The stitchwelder for even higher production runs |

| VSTW 1000/1270/1524 | The manual stitchwelder for longitudinal seams |

| VSTW-R | The manual stitchwelder for round pieces |

| VSTW-RBi-RBa | The manual stitchwelder for inside and outside pipe bends / elbows |

| VARB | The automatic half-shell welding machine |