Test facilities at ANDRITZ Laroche

ANDRITZ machines and equipment for textile recycling lines

Perfectly matched machine components for the textile tearing lines and for airlay processing

ANDRITZ offers not only the machine technology for textile recycling but also all other components for building a complete recycling line. All machines are matched to each other and offer the best possible productivity and thus excellent results in all steps of the recycling process.

Start with sorting textile waste

The automated sorting process

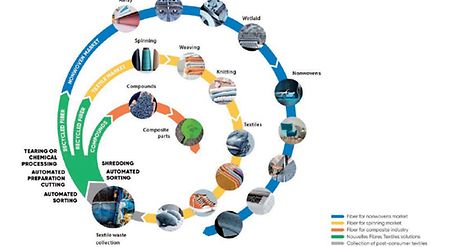

Innovative automated sorting makes it possible to separate parts of clothes by color and/or raw material. During this automated process, hard points are removed via tearing to obtain a material ready for mechanical recycling. We offer a wide range of tearing machines, which are suitable for many applications, for both spinning and nonwovens markets.

Collaboration leads to success

The unique process for automated sorting is the result of a long-term collaboration between ANDRITZ,

Nouvelles Fibres Textiles, and Pellenc ST, France. Combining decades of expertise and know-how in

sorting technologies by Pellenc ST, post-consumer textile value chains from sorting to manufacturing by Nouvelles Fibres Textiles, and textile machinery and processes by ANDRITZ, we succeeded in finding the best solution for the huge challenge o f textile sorting.

Picker shredder

For ideal pre-opening and cleaning: The picker shredder machine is specially designed for old rags, carpets, and moulding wastes. Adjustable setting while running. Accessories: fiber lubrication. Option: cleaning device.

ANDRITZ picker shredder

Cutting system

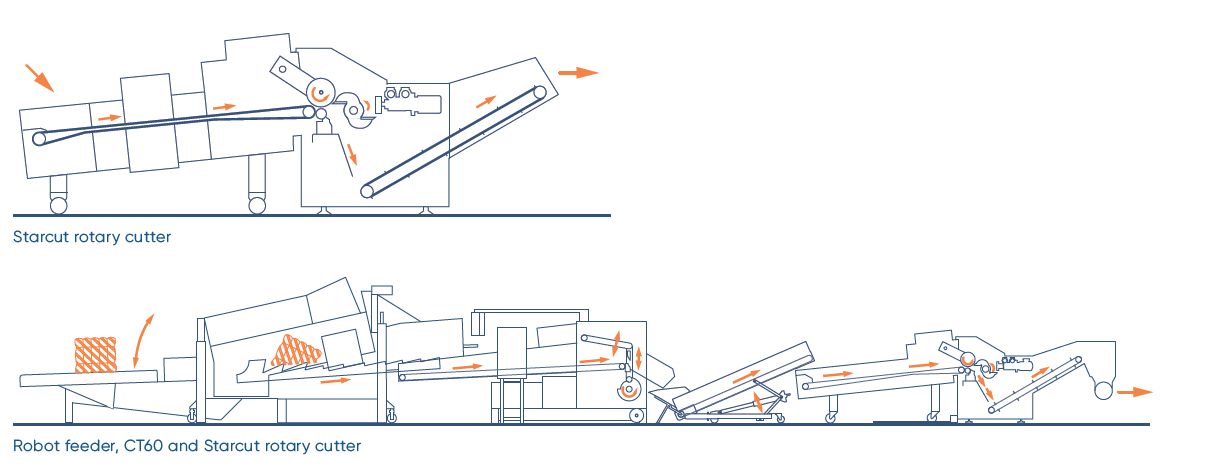

For an accurate and flexible cutting process: Our solutions range from simple systems with one or two rotary cutters to complete cutting plants. The Starcut rotary cutter is equipped with a cut ting head with two or four flying knives and a feeding conveyor rolling out of the machine for easy access. This machine is also equipped with a built-in sharpener. We also optionally provide a metal detector and a dedusting system for the cutting head.

ANDRITZ Starcut cutting system

ANDRITZ Starcut cutting system

Baling system

Full range of fiber baling systems. Vertical baling press: Pressure from 100 to 200 t.

ANDRITZ baling system for uniform compression of the fibers recovered

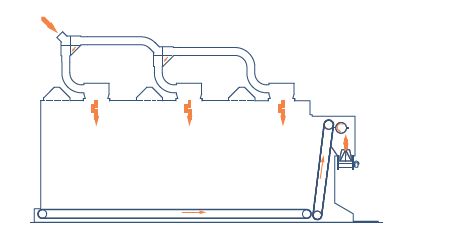

Blending box

Guaranteeing blend homogeneity: In order to ensure long-term blend consistency, we provide a wide range of blending boxes with a working width of 3,000 to 3,900 mm and a storage capacity of 35 to 300 m3.

Blending box SM 3000/4 and blending box SM 3000/10

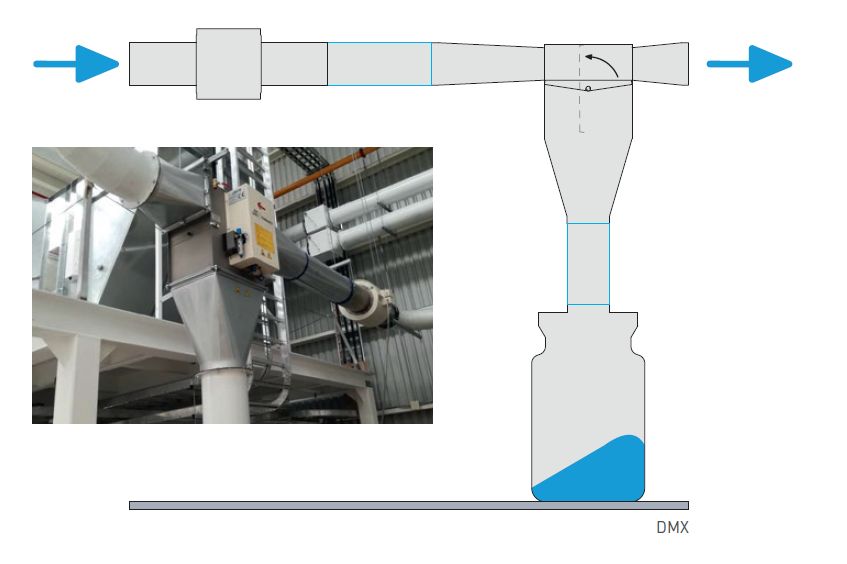

Metal detection DMX

Highly sensitive metal detection and automatic rejection of contaminated materials.

Can be combined with fire detection system.