ANDRITZ Soutec AG, Switzerland

Rotfarb 4

8413 Neftenbach

The Soutrac is an evolutionary welding machine.

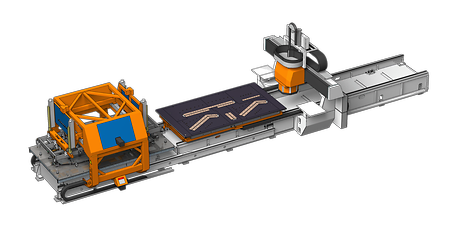

Soutrac, laser welding system for curved seams

Soutrac welds individual TWBs (welded tailored blanks) with several different welding seams and different sheet metal thicknesses per part in one operation.

The heart of Soutrac is built on a 10-axes welding head that allows us to weld curved applications. The continuous measurement seam tracking and quality control system guarantees a stable welding process, meeting the highest quality requirements. Gaps of <0.3 mm between the sheet metal are closed adaptively with Soufil wire.

With the aid of our continuous gap closing and vision system, we are able to regulate the wire speed to ensure that sufficient material is always present in the melting pool.

Example of a Soutrac layout

| Parameter | Value |

| Maximum welding range | 3,800 mm x 2,200 mm |

| Maximum blank size | 4,700 mm x 3,300 mm |

| Minimum blank size | 300 mm (smaller size on request) |

| Smallest radius | 75 mm |

| Maximum blanks per cycle | 8 |

| Maximum welding seams per cycle | 24 |

| Laser source | fiber laser, disk laser, or diode laser |