Our pusher centrifuge ensures maximum online availability with minimum maintenance and low space requirement in many solid/liquid separation processes.

Pusher centrifuge ecoOne to maximize efficiency

The ANDRITZ pusher centrifuge ecoOne is a high-performance solution for continuous solid/liquid separation in industrial applications. Designed for efficiency, reliability, and adaptability and to reduce energy consumption, it combines proven basket centrifuge technology with modern innovations to meet the evolving needs of the chemical, food, and mineral industries.

Pusher centrifuge, understanding the fundamentals

A pusher centrifuge is a type of continuous solid/liquid separation equipment used primarily for dewatering crystalline or amorphous materials. It uses a rotating perforated basket and a reciprocating pusher mechanism to move solids through the basket while allowing liquid to pass through. This design enables high-throughput and efficient separation.

Single-motor design for lower energy consumption

How the ecoOne motor reduces power usage by up to 20%

Unlike conventional centrifuges that have a separate pusher and drive motor, the ecoOne employs a single, integrated motor. This design ensures that the motor operates within its optimal efficiency range during both startup and regular operation. As a result, installed and absorbed power is reduced by up to 20%, significantly lowering electricity costs and the machine’s ecological footprint.

Benefits of combining pusher and drive functions

The dual-function motor allows for dynamic load balancing: reserve capacity used during startup can be repurposed for pushing during operation. This not only improves energy efficiency but also simplifies the mechanical layout, reducing the number of components subject to wear.

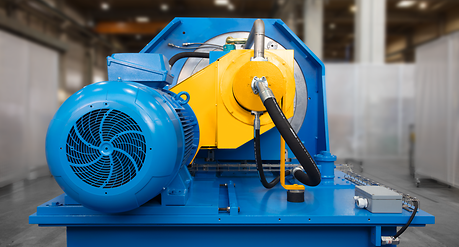

ANDRITZ pusher centrifuge ecoOne with a combined pushing and drive motor

Advanced technical features for enhanced performance and flexibility

PreFiltration technology: integrated thickening for better separation

The PreFiltration design maintains a free-draining area throughout the pushing cycle. This increases the liquid handling capacity and makes the centrifuge ideal for feeds with low solids content or high viscosity, ensuring consistent throughput and separation quality.

GentleFeeder™ system: minimizing particle breakage

An underestimated problem is particle breakage. This occurs in almost all centrifugation processes and is problematic because high fines in the discharged product are usually undesirable. It also has a negative effect on the residual moisture of the cake, and the loss of fines into the filtrate. Although pusher centrifuges already treat the solids relatively gently, as they do not require a conveying device such as a screw to transport the solids, investigations have shown that high shear forces and corresponding particle breakage occur in the area of the feed system.

In the feed area of a pusher centrifuge, the suspension is accelerated to a circumferential speed of over 100 km/h over a distance of a few decimeters. If this is not done in a directed and uniform manner, high shear forces occur, which lead to heavy wear in the centrifuge and particle breakage. ANDRITZ centrifuges use the well proven GentleFeeder technology, in which a geometry reminiscent of a pump impeller gently accelerates the suspension.

Cartridge design: fast maintenance with minimal downtime

Pusher centrifuges are often operated with highly corrosive and abrasive products. In such applications, regular inspections and maintenance are essential to ensure the efficiency and safe operation of the centrifuges. ANDRITZ pusher centrifuges rely on the well proven cartridge technology. The entire rotating unit is pulled out of the centrifuge in one piece without having to disconnect the machine's piping. During maintenance, a replacement cartridge from stock can be installed, so that the interruption of production is usually less than one shift.

Processing parameters of the ecoOne pusher centrifuge

| Average particle size | 80 – 10,000 µm |

| Solids throughput | Up to 150 t/h |

| Solids recovery | Up to 99 % by wt. |

| Feed solids concentration | Up to 80 % by wt. |

| Basked diameter | 250-1,250 mm |

Adaptable design for evolving process requirements

Easy conversion from two-stage to three-stage operation

The ecoOne basket system is engineered for on-site conversion between two-stage and three-stage configurations. This allows operators to adapt the machine to changing process conditions without replacing the entire basket assembly—an economical and future-proof solution.

Lightweight and compact footprint for space optimization

With a 10% reduction in weight and footprint, the ecoOne is easier to install and integrate into existing process lines, especially where space is limited.

Additional benefits of the ecoOne design at a glance

- The consumption of lubricant is reduced by 40%

- The weight is reduced by 10%

- The footprint is reduced by 10%

- Easy conversion from 2 stages to 3 stages

Applications across industries

Bulk chemicals and technical salts: Ideal for sodium chloride, sodium sulfate, soda ash, and lithium hydroxide, the ecoOne delivers high throughput and consistent performance under demanding conditions.

Agrochemicals and fertilizers: Handles products like ammonium sulfate, MAP, and potash with precision, ensuring low residual moisture and high solids recovery.

Plastics and polymers: Suitable for ABS, paraxylene, polycarbonate, and adipic acid, the centrifuge maintains product integrity and minimizes fines.

Smart control with Metris addIQ: optimizing centrifuge performance

To further enhance performance and reliability, the ecoOne can be equipped with the Metris addIQ control system – a modular, PLC-based control system tailored specifically for filter centrifuges. This intelligent control solution supports real-time monitoring, predictive maintenance, and process optimization. Find out more about Metris addIQ for filter centrifuges.