In case of emergency

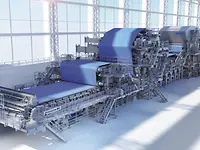

As in all industrial processes, even with scheduled maintenance, unplanned problems and events do occur. ANDRITZ Novimpianti has skilled people covering all eventualities at its service centers, who are dedicated to keep paper and tissue machines and processes running, with advice and readily accessed spare parts.

ANDRITZ Novimpianti runs its spare parts division on a just-in-time basis with critical components always in stock to avoid a complete breakdown.