Creating impact and added value

Producers of soda ash and technical salts are looking for ways to meet the high demand for their product, while at the same time meeting the demand for greener, more efficient and sustainable production. The production processes and means of transportation are being reviewed and renewed.

ANDRITZ supports this with research and pilot plant tests executed by knowledgeable and highly skilled process engineers.

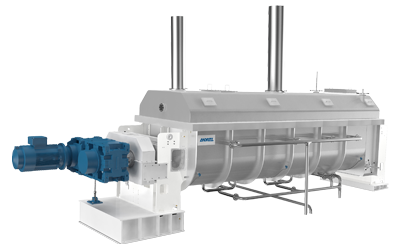

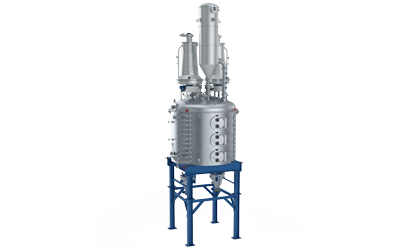

Pioneering dewatering and drying solutions

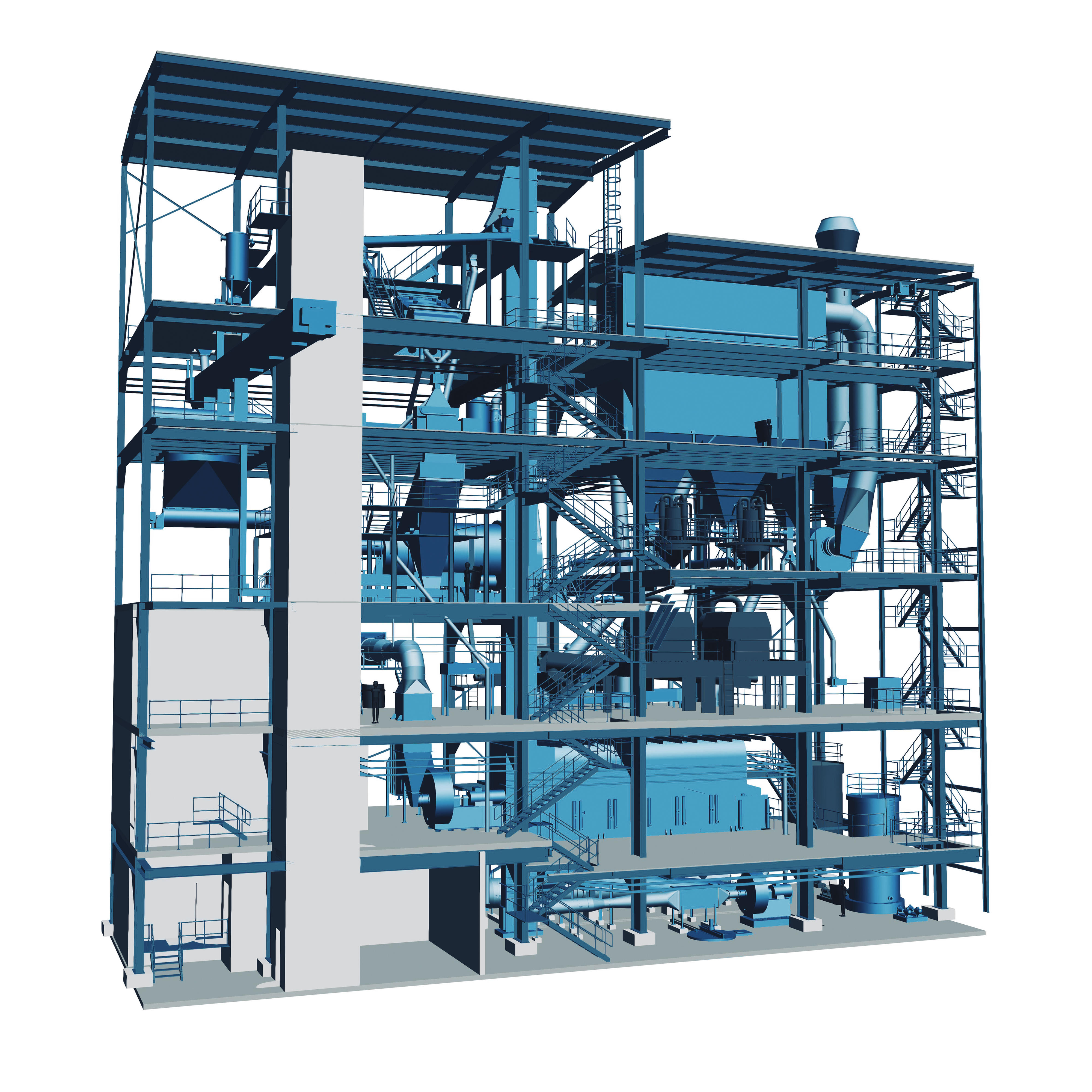

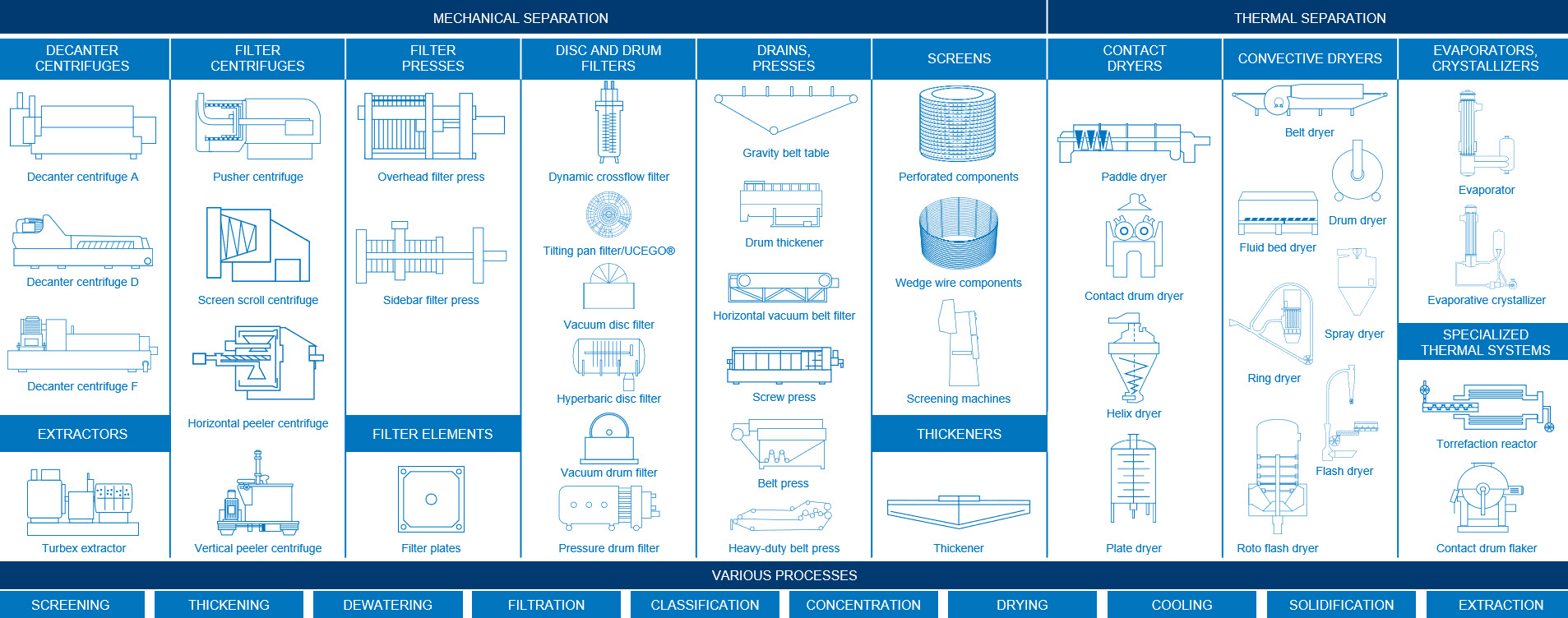

As many of the soda ash and technical salt manufacturing processes involve solidification, thickening, dewatering, drying, calcination and cooling, ANDRITZ separation specialists are working in close collaboration with the industry to develop green production plants that meet consumer demands.

Our pilot plants around the world determine and test next-gen dewatering and drying solutions. Whether the customer is a start-up with a great idea for creating new applications or upcycling waste, or a known partner with a need to improve efficiency in an existing process, our team is there to support them. All backed up by modern automation solutions.

Want more information?