ANDRITZ supplies centrifugal pumps for industrial applications and processes in the food industry, particularly sugar and starch.

Leading solutions for producing native and modified starches

Whatever separation, dewatering or drying challenge you are looking for, we have the right solution for you.

An indispensable, sustainable ingredient for many products

Did you know that starch is not only used in the kitchen for thickening sauces or bakery? It is also applied as a binder and stiffener in the textile and paper industry and animals love their feed, because it contains starch which gives a great taste and feel. Starch is a natural ingredient that helps us taking care of nature by extending shelf life and by replacing fossil fuel based products in – for instance – plastics and detergents.

Like starch manufacturers nowadays, ANDRITZ is also adjusting to the consumers‘ demand for healthier, more sustainable and natural products. The focus lies on clean label, non-GMO, vegan and gluten free. This is why new and innovative processes in starch manufacturing focus on natural starches without chemical modification. Depending on the end product A- or B starches are applied.

Key application areas

Where we fit into your process

Corn starch

Wheat starch

Tapioca starch

Potato starch

Process know-how and broad portfolio

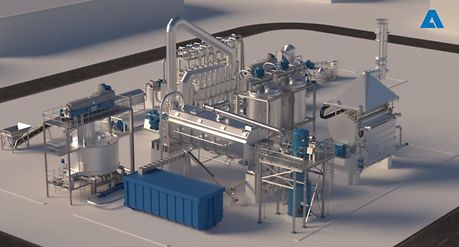

ANDRITZ specialists obtained extensive knowledge on starch processing through multiple projects at different starch manufacturers production plants all over the world. They know that each type of raw material, being it corn, wheat, rice, potatoes, peas or tapioca, requires a different production method. With more than 400 starch installations worldwide, ANDRITZ has a proven track record of excellent results with very little downtime.

Our proven solutions for the starch industry do not only ensure hygienic operation and maintenance friendliness but also use very low energy and obtain highest yield and starch quality.

Discover our solutions for your success

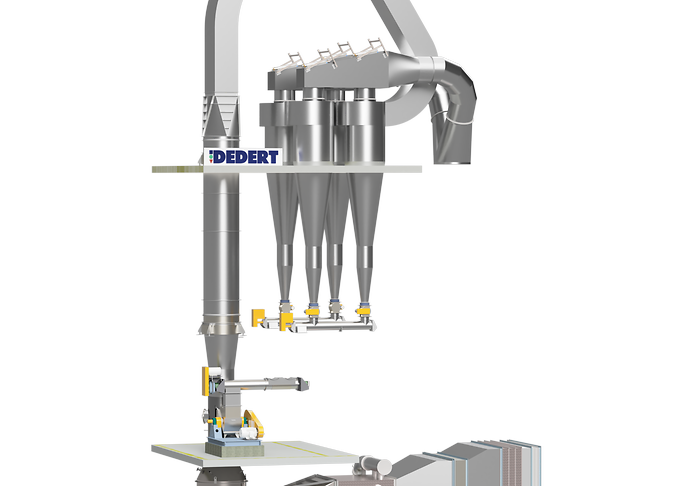

Our portfolio covers the main equipment in nearly every starch processing line from degermination mills, decanters, peeler centrifuges, vacuum drum filters as well as contact drum dryer gluten screw press, ring and flash dryers, spray dryers and evaporators for modified starch or paddle dryers for dextrinization. We also offer a range of pumps for the entire wet process or screening systems like DSM or centrifugal screens which remove the fibers from the starch.

Your full-service provider

Your full-service provider

Intelligence for machine and process control

Intelligence for machine and process control