Put our 150 years of OEM experience to work!

Efficient separation solutions for producing palm oil

ANDRITZ offers the right solutions to meet the separation needs of palm oil producers and users

Palm oil is one of the most important commodities in the world’s oil, fat, and biofuel markets. ANDRITZ is the only supplier that offers decanters, filter presses, screw presses, belt presses, and spray congealers, providing the right solutions to meet the separation needs of palm oil producers and users. Whatever the step in the palm oil production process—crude oil extraction, POME treatment, biogas sludge treatment, crude palm oil refining, or oleochemicals drying—a proper solid/liquid or oil/water separation phase is needed to meet the requirements of the final product.

Palm oil milling (Conventional/underflow process)

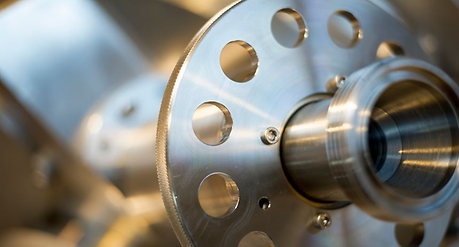

The unique design of ANDRITZ decanter centrifuges, such as the combination of the open flight and the feed port, results in gentle product feed and minimal shear force on the product.

As a result, oil recovery is improved because of less stress and turbulence. In addition, the precise pond level adjustment is essential to optimize the recovering efficiency of the decanter, and the pipette device makes it easier to adapt the required oil purity and keep oil losses in the heavy and solid phases under control.

This optimization will reflect an increase in the final Oil Extraction Rate (OER). Proper process integration with the ANDRITZ 3-phase decanter can eliminate the further usage of the nozzle separator, reducing the POME volume and energy consumption. ANDRITZ decanter centrifuge F for palm oil for the underflow process comes with a fully automated PLC/VFD-based operation with torque control and many other control options.

ANDRITZ decanter centrifuge F5000

Adjustable pipette in operation to adapt the required oil purity easily

POME digestate and biogas production

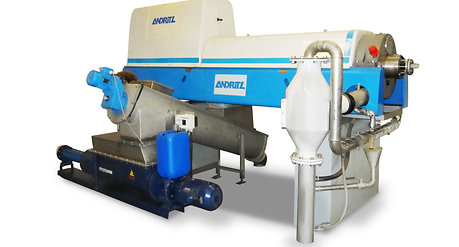

For palm oil mill effluent (POME) dewatering from anaerobic ponds or digestate dewatering, palm oil millers are looking for low-energy and low-maintenance solutions. The ANDRITZ decanter centrifuge D is maintenance-friendly, with very competitive maintenance costs. The high-performance, open-flight conveyor contributes towards ensuring good dewatering behavior. There are many customizable options available to match the customer's requirement, so that the exact performance can be achieved as per the customer’s expectation.

ANDRITZ decanter centrifuge D for POME and biogas application

Palm oil refining (dry fractionation)

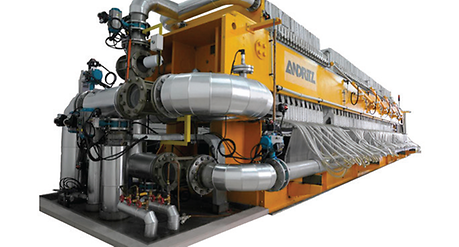

Dry fractionation is a process of separating the solid and liquid phases to yield olein and stearin. The temperature of raw palm oil is maintained at around 70°C and homogenized to destroy any crystals that may have formed beforehand. Crystal formation and growth occur as the oil is agitated, and the cooling process is controlled using chilled water circulation until the oil reaches the required temperature of around 22°C. The slurry is then fed into the membrane filter press. The membrane plates are inflated with air, water, or oil to squeeze out the entrained olein.

ANDRITZ filter presses have been developed with multiple safety features in the machine components, providing greater operating reliability and helping achieve good and consistent product quality with a high olein yield. In addition to a safe and reliable design with low operating costs, ANDRITZ filter presses are built with superior quality.

For more sustainable production methods, ANDRITZ’s innovative palm olein power pack (POPP) offers a way to save filter press hydraulic oil expenditure by up to 80%. The POPP enhances food safety by driving the hydraulic system with palm olein, a superior alternative to food-grade mineral hydraulic oil. In the event of a spill, the oil will not be contaminated.

Furthermore, the POPP allows substantial cost savings by recycling palm oil and eliminating the need for mineral oil or food-grade mineral oil.

ANDRITZ filter press for palm oil refinery (dry fractionation)

Palm olein power pack to improve food safety standards

Spray congealing technology for palm stearin

To precisely control the particle size of palm stearin, a spray congealer may be required. Depending on the desired particle size, various atomization methods such as a rotary atomizer, high-pressure nozzles, or a fountain nozzle can be employed.

The fine particles from the atomization and cooling processes are carried through the air exhaust duct and are either discharged via a bag filter or fed into the VIBRO-FLUIDIZER™ system. To provide additional cooling and manage the heat generated during crystallization, a VIBRO-FLUIDIZER™ fluid bed is positioned below the spray cooling chamber.

For atomizing extra-coarse particles (500-2000 microns, or prills), a fluidized spray cooler is the ideal solution. This system includes a low-speed rotary atomizer with a specially designed prilling wheel in its large-diameter chamber. An integrated fluid bed, featuring a perforated plate at its bottom, introduces cold air to facilitate simultaneous fluidization and solidification of the prills.

Dedert rotary air bearing atomizer for spray congealing process

Spray congealing process diagram