Put our 150 years of OEM experience to work!

Efficient tailings dewatering solutions for sustainable mining operations

Higher dryness and maximized water recovery with lower energy consumption? Or high specific throughput with a minimum equipment footprint? Whether you are aiming to increase water recovery, ensure safe dry stacking, or aim for efficiency optimizations for treatment of coal, copper, gold, iron ore, lithium, sand or other tailings, we have the ideal thickening and dewatering solution for you!

All issues attached to tailings treatment – environmental risks, space constraints, and water scarcity – need to be managed as cost-effectively as possible, as the result is a waste product rather than one that turns a profit. This is why we have developed a broad portfolio, including a wide range of individual technologies as well as line solutions, that can be tailored to help you achieve your goals at the optimal OPEX or CAPEX for your specific operations. From new equipment and systems to upgrades of existing processes, our process audits can help you identify the best opportunities for enhancing productivity, safety, and capacity for practically any tailings stream. Combined with process simulation technology, machine and process control and proven local service, we are proud to be able to offer the full package from simulation to installation and process optimization.

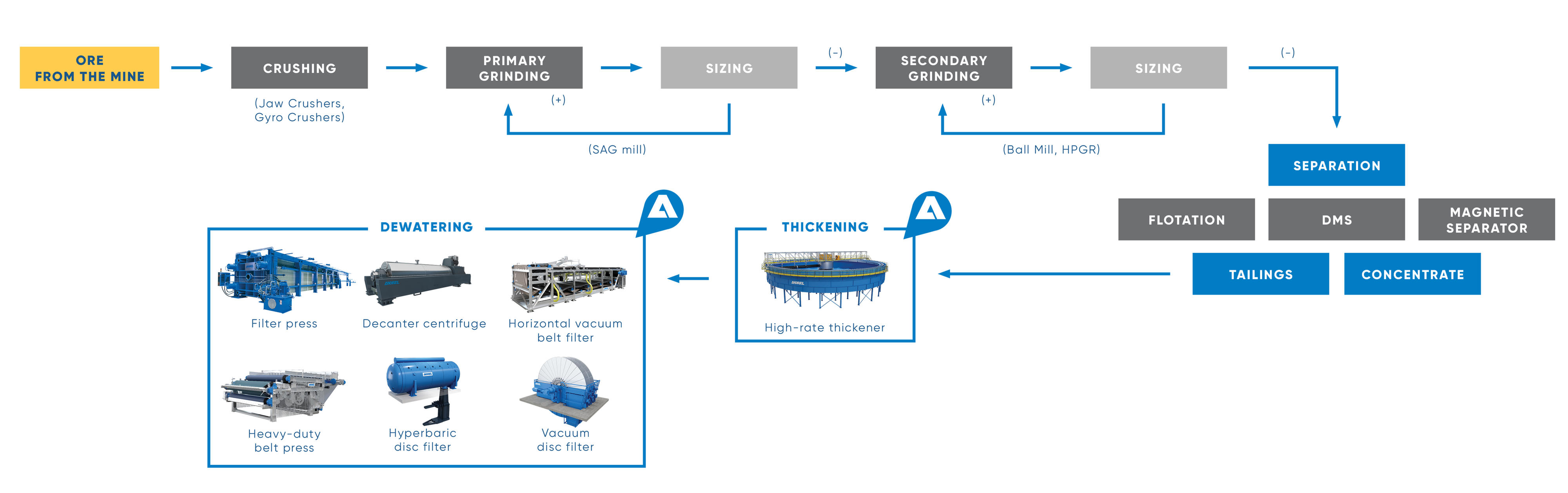

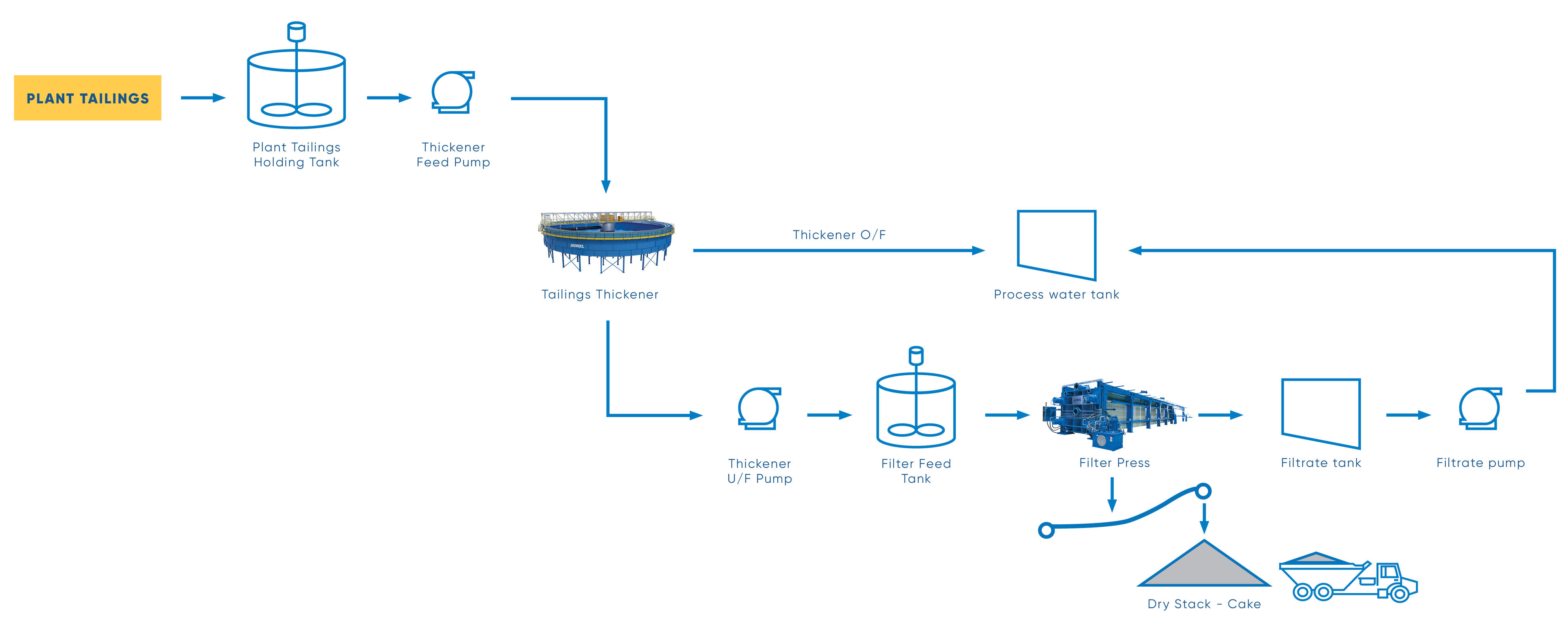

Where we fit into your tailings process

ANDRITZ specialists have gained an extensive knowledge of tailings treatment processing through multiple projects at various mining and mineral companies all over the world., for more than a century. We have invested considerably in expanding our competence with the acquisition and integration of well-known names as Bird, KHD Humboldt Wedag, Rittershaus & Blecher, Netzsch Filtration, Escher Wyss dryers, Krauss-Maffei centrifuges, dryers, and filters, and Delkor Capital Equipment (Pty) Ltd. We at ANDRITZ know how to tailor our complete range of state-of-the-art technologies to meet your needs. And by exploring innovative new ways to safely handle tailings or automate and monitor remote facilities, we ensure that you are ready for the future as well.

Complete tailings installations

Flowchart for dry stacking applications