ANDRITZ Soutec AG, Switzerland

Rotfarb 4

8413 Neftenbach

The state-of-art bipolar plate manufacturing.

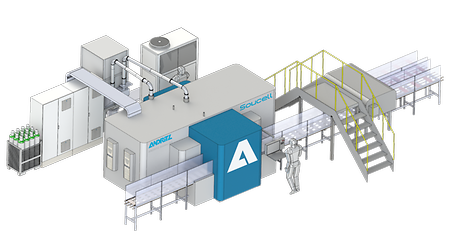

Laser welding system Soucell

The bipolar plate (BPP) is an important component of fuel cells; up to 400 such plates are put together into the so-called stack. This makes the BPP a key component. ANDRITZ Soutec is offering -analog to the Soutec highspeed laser welding system SOUSPEED- a system that welds fast and in the required high quality. SOUCELL makes it possible; based on a reference design*, a production rate of up to 1 Hz is feasible (=1 BPP per second).

*based on a benchmark weld seam length of 2.5 m

High precision machine, produces high quality weld seams

Small floorspace required

Scalable to required production volume

Welding in a single clamping, no reclamping necessary

Easy and flexible integration into existing production lines

Technically maximum possible beam-on-time

Resource-saving with regard to welding gas

World novelty, from the world's leading TWB welding specialist in Switzerland

Parameter | Value |

BPP-Dimension max: min: | 500 x 230 mm 200 x100 mm |

Productivity: | ≤ 3’600 BPP/h (1 Hz) |

Machine-Dimension L: W: H: | 6.7 m 3.7 m 2.1 m |

| Conveyor Speed Vc: | ≤ 15.6 m/min |

Conveyor BPP partition | 260 mm |

Number of laser units | Depending on BPP design and required output |