A custom model. A clear path forward.

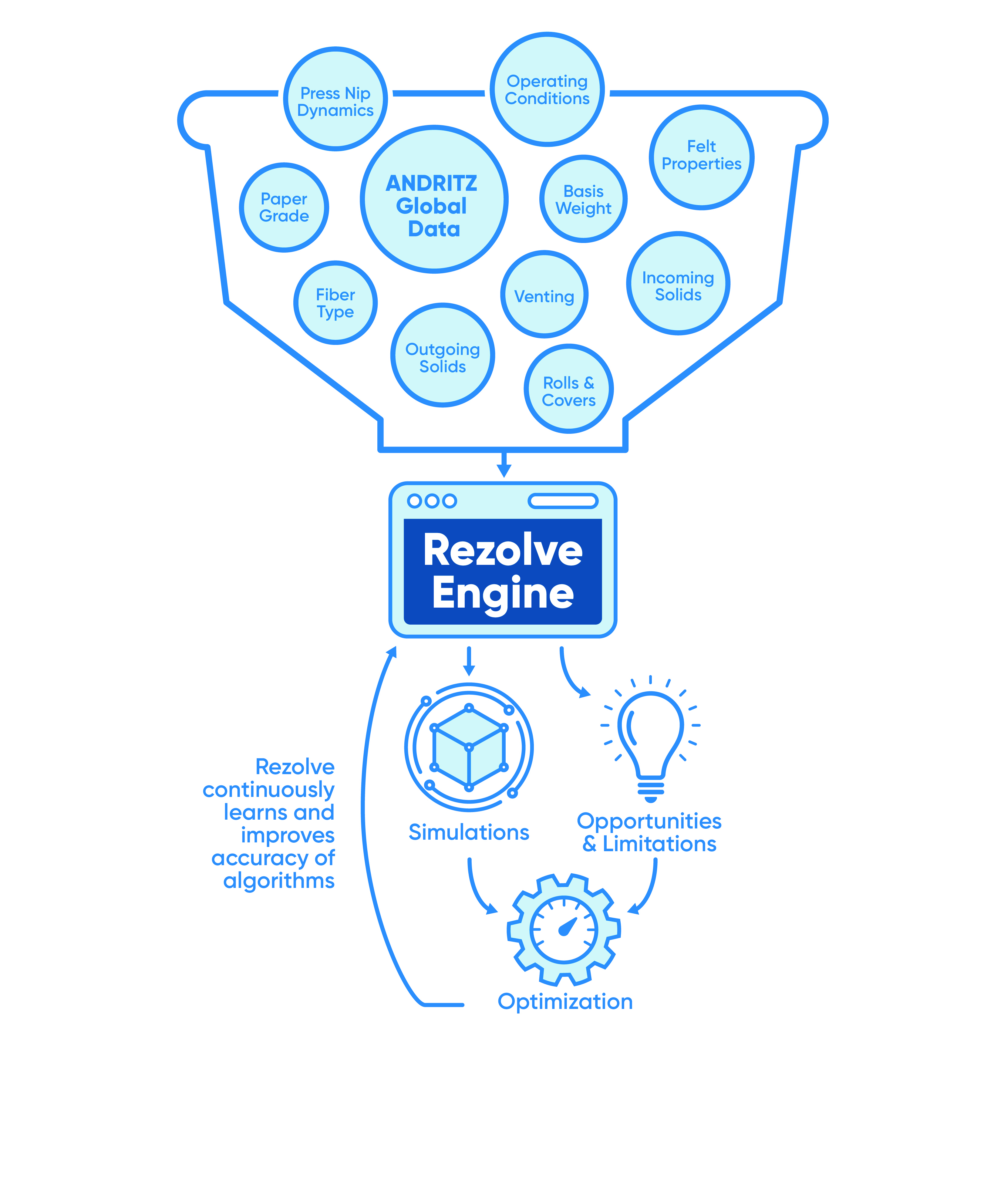

Every Rezolve deployment begins with a full system assessment: your fiber mix, press felt, rolls, water and vacuum systems. From there, we build a digital model of your press section, complete with real-world variables like press nip dynamics, drainage paths and sheet response.

You’ll be able to test “what-if” scenarios virtually – before making changes to the machine. The result is a smarter way to optimize, plan upgrades and extend asset life.

If you want to move faster, run cleaner and make informed decisions with confidence, Rezolve is your starting point.