Facing challenges with screenings or grit removal efficiency? Looking for reliable fine screening solutions to protect downstream processes? Need compact, low-footprint solutions for tertiary filtration? Trying to reduce sludge volume and cut disposal costs? Looking to optimize thickening, dewatering, or drying performance?

At ANDRITZ, we have the largest range of technologies available to handle these challenges. Therefore, we are able to advise and support you in selecting the right technology for your project. Many parameters can influence the design and operations of a wastewater treatment plant, but often the most critical parameters are the local conditions.

We, at ANDRITZ, can take these conditions into account, evaluate them with you and only then help you select technology. This product agnostic path is the safest most efficient one to ensure that your plan will be equipped with long-term performing and reliable technology. We support you in finding the right solution and the most suitable product for your needs. With a wide range of technologies, we offer tailored advice and reliable expertise to ensure optimal results.

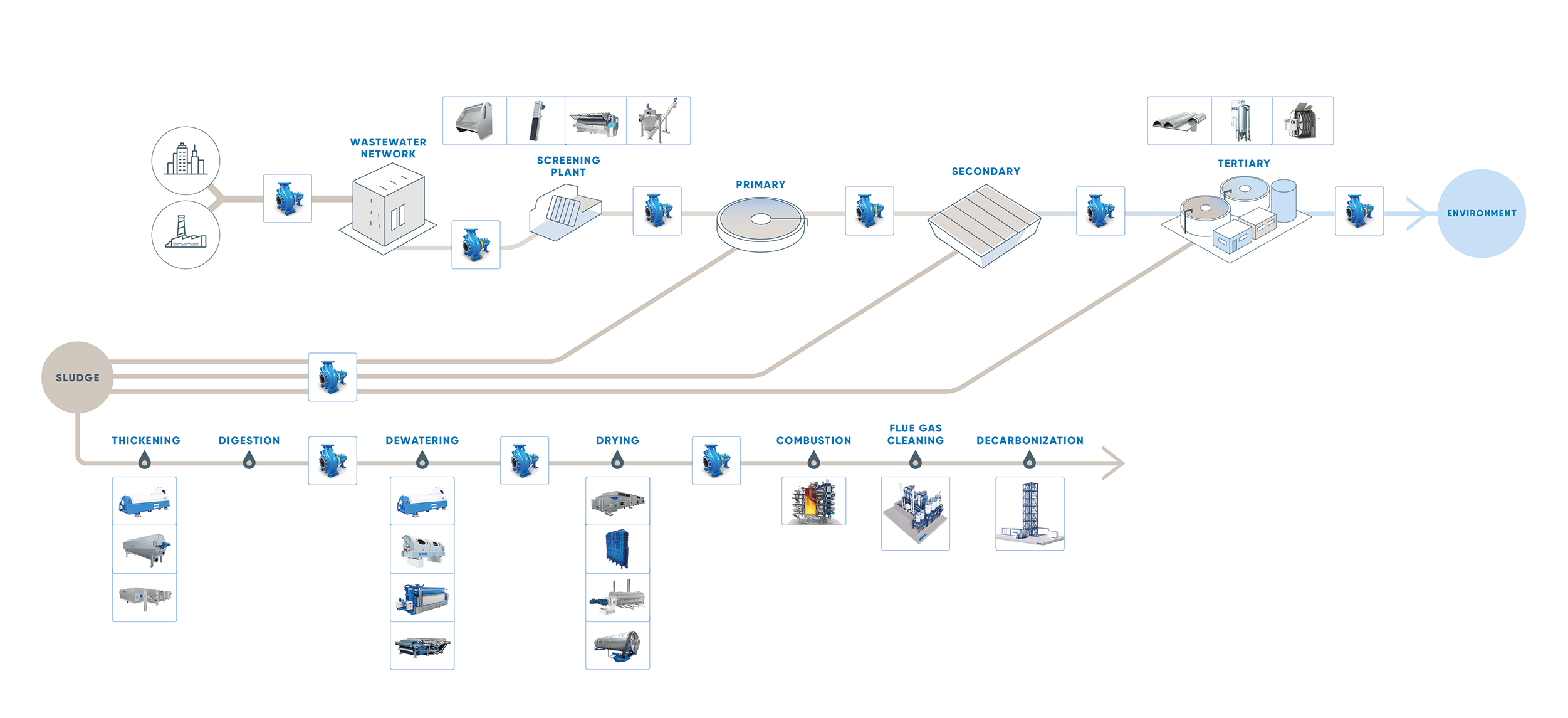

We are proud of being able to deliver more wastewater treatment technologies than any other supplier, covering the entire wastewater and sludge treatment process (all from liquid sludge to dried Class A biosolids), including three thickening technologies, four dewatering technologies, and four drying systems, together with a complete range of in-house screening, ancillaries as well as proven service and automation technologies.