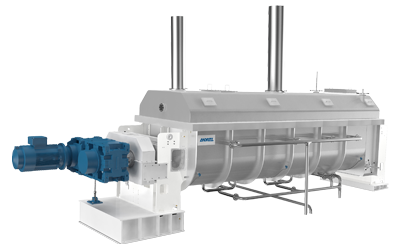

Sustainable and innovative processes

It is no secret that substantial parts of the animals we consume are discarded because they are not edible (e.g. skin or bones). But fortunately, sustainable ways of processing these parts are rapidly increasing and helping to ensure that a growing number of nature’s resources can be recovered and returned to the food and feed chain in the form of useful ingredients, such as protein, peptides, gelatin, collagen, fats or minerals. Like food manufacturers, ANDRITZ is also adjusting to consumers’ demands for natural, pure and allergen-free nutrients and has, therefore, developed new ways to secure nature’s gifts, with innovative process solutions that turn animal raw materials into sustainable food, feed and fuel ingredients.

Contact us today to learn more