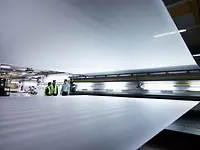

From complete tissue production lines down to single components, ANDRITZ delivers state-of-the-art tissue and air drying technology.

New PrimeLineTEX tissue machine for textured tissue

ANDRITZ has officially launched its new tissue machine for textured tissue, the “PrimeLineTEX”, enabling customers to produce textured tissue of a quality superior to dry crepe and very closeto structured (TAD) tissue, while at the same time achieving significant cost savings.

PrimeLineTEX is available with widths of 5.6 or 2.8 m and produces high-quality tissue for towel and sanitary applications. The machine offers up to 25% fiber savings compared to dry crepe and consumes up to 50% less energy than a TAD machine. The PrimeLineTEX is substantially shorter in length than other market solutions and uses only one additional fabric instead of two. Furthermore, the PrimeLineTEX machine can switch between production of textured and dry crepe tissue within a much shorter time than comparable solutions.

“Our new PrimeLineTEX tissue machine enables customers to produce high-quality tissue close to TAD but with substantially reduced investment and operating costs. It is available to all markets worldwide, without any restrictions. This new machine offers profitable advantages for our customers,” says Klaus Blechinger, Vice President Tissue at ANDRITZ. As a turnkey supplier, ANDRITZ can offer the complete textured tissue production line, including stock preparation, pumps, and the automation system.

For more information, please go to: