Key application areas

Whether you’re producing or recycling ABS, BPA, HDPE, melamine, PC, PET, PMMA, PVC or PX, we have the in-depth process knowledge and a range of technologies to help make your operation successful.

The petrochemical and polymers industry produce materials that are suitable for use in our daily lives. They are either strong, transparent, adhesive, insulating or resilient. Or they have more than one of these properties that respond to the requirements of the end-user. Due to their versatility, they are used in a wide variety of applications.

Petrochemicals and polymers are all around us – be it in our clothing, the tires on our cars, packaging material for our food and beverages, laundry detergents, or our electronic equipment—the building blocks that enable the manufacture of most of these goods are provided by chemical and plastic materials. To answer up to the changing laws, the EU’s Green Deal, and other regulations, the petrochemical industry is committed to further improving production and recycling processes through research and development. And ANDRITZ is here to help.

Whether you’re producing or recycling ABS, BPA, HDPE, melamine, PC, PET, PMMA, PVC or PX, we have the in-depth process knowledge and a range of technologies to help make your operation successful.

ANDRITZ understands the challenges that the petrochemical and polymer industry is facing. Building on our “We Care” program, all systems and plants supplied by ANDRITZ comply with the strictest environmental, safety and technology standards (best available technologies). The focus is on recycling and re-using, for instance of plastic bottles and superabsorbents.

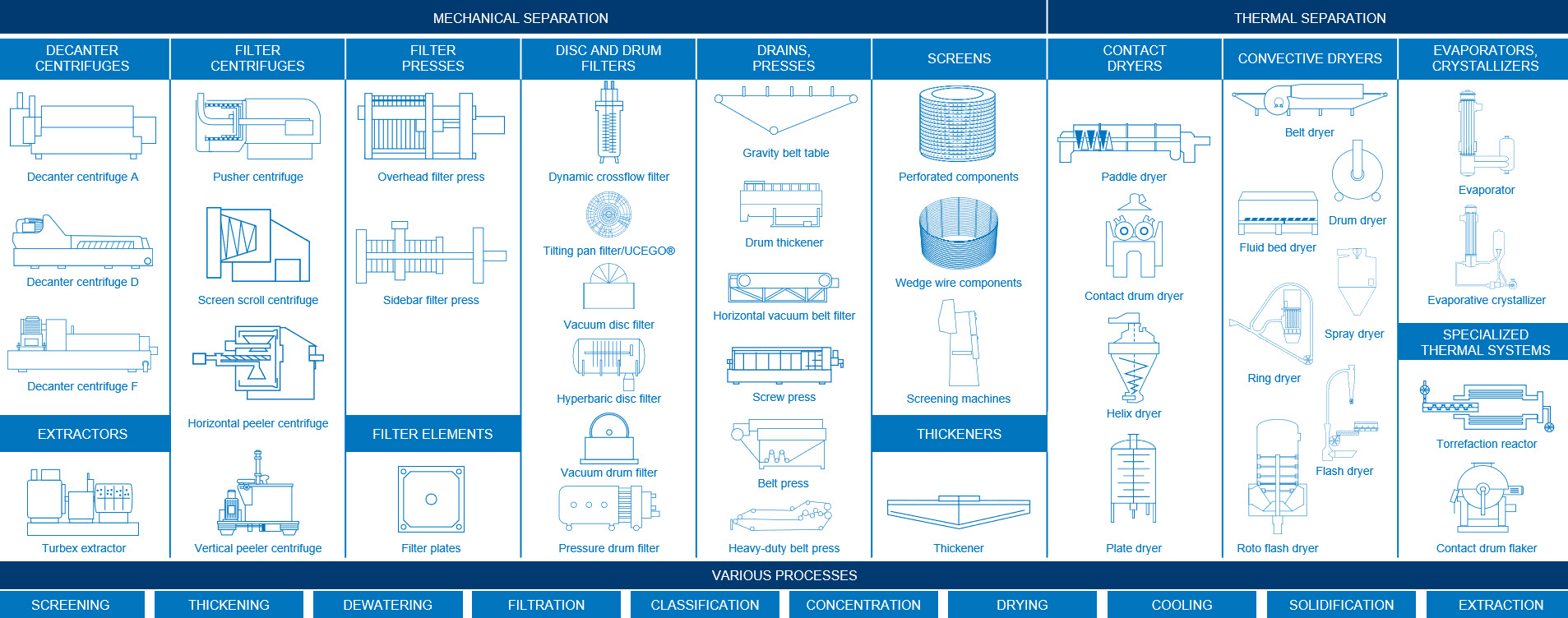

Centrifugation, drying, separation or filtration - However your product is created, we most likely have everything to separate it into its component parts: the technology, the process knowledge, and also the service and automation solutions. ANDRITZ equipment helps you to manufacture the petrochemicals and polymers of the future. In our pilot plants, we help you to find zero-waste and zero-emission ways to manufacture your product.

with solutions for chemical and mechanical plastic recycling.

Chemical PET recycling process

Mechanical PET recycling process

Hydroprocessing reactors in the refining and petrochemical industries require very specific designs to achieve good performance over the years and minimize maintenance turnaround.

ANDRITZ Euroslot delivers production units for reactor internals to achieve optimum and trouble free operations, considering the following parameters as key elements:

ANDRITZ specialists have obtained extensive knowledge on dewatering, filtration and drying through multiple projects at different (multi-national) petrochemical manufacturers’ production plants. They know that each type of raw material, be it plastic or polymer, requires a different production method. With an endless number of installations worldwide, ANDRITZ has a proven track record of excellent results with very little downtime.

With our current portfolio, we are able to respond to the requirements for recycling, reusing and reducing as well as for efficient manufacturing with low energy consumption.

Your full-service provider

Your full-service provider

Intelligence for machine and process control

Intelligence for machine and process control

Increased centrifuge throughput in plastic recycling

Increased centrifuge throughput in plastic recycling