When you’ve been in business for 130 years, you learn a few things about adapting to change. So when Germany introduced new emissions targets, UPM’s Schongau mill stayed ahead of the game with a major upgrade of its bubbling fluidized bed (BFB) boiler. Welcome to futureproofing.

Did you know that ...

…. ANDRITZ gasification plants are using woody biomass as fuel?

The ANDRITZ gasifiers are based on circulating fluidized bed (CFB) technologies. As a fuel, biomass replaces oil or natural gas and helps pulp mills reduce their overall greenhouse gas emissions (GHG). The approximate capacity can go up to 150 MW of product gas. Read more about biomass gasification in the article ‘A major step to reduce carbon footprint in pulp mills’ in SPECTRUM NOW.

The Holmen Group’s Braviken Paper Mill, situated in eastern Sweden, has always prided itself on being at the top of its game when it comes to production efficiency and quality of final product. When it needed to further enhance its TMP’s capacity and efficiency – but crucially keep costs to a minimum – ANDRITZ was at hand to provide a tailor-made solution.

Henan Tianbang Group Paper Company takes enormous pride in the quality of its fine paper products that are known and used in China and around the world. When the company decided to end its dependence on market pulp and produce its own mechanical pulp, ANDRITZ was the first to be called.

The largest engineering projects northern Sweden has ever seen was completed recently with the doubling of capacity at SCA Östrand’s softwood kraft pulp mill. The project – named Helios after the God of the Sun in Greek mythology – is now setting a new global benchmark in high-performance pulp production. ANDRITZ supplied some of the latest key technology to the completely rebuilt mill.

Metsä Group gave permission to the SPECTRUM editorial team in early October 2018 to share a DAY IN THE LIFE of Ilkka Poikolainen, Vice President of the bioproduct mill in Äänekoski

Major research of nonwoven raw materials, applications and production models and methods are all in a day’s work for the European Center for Innovative Textiles (CETI) in France. The latest ANDRITZ state-of-the-art air-through bonding nonwoven technology is right at the heart of the center’s globally renowned research.

When you´ve been in business for 130 years, you learn a few things about adapting to change. So when Germany introduced new emissions targets, UPM´s Schongau mill stayed ahead of the game with a major upgrade of its bubbling fluidized bed (BFB) boiler. Welcome to futureproofing.

More than three decades ago, Pietro Saccomano co-founded Novimpianti, an Italian firm specializing in air systems and reducing energy consumption. More recently, the Lucca-based company has focused mainly on tissue mills. Earlier this year, Novimpianti became ANDRITZ Novimpianti, part of the ANDRITZ Paper & Tissue Division. We spoke about the deal with Pietro Saccomano and Klaus Gissing, Director of Air & Energy Systems and the new tissue pilot plant PrimeLineTIAC within ANDRITZ Paper & Tissue.

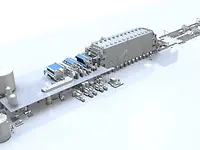

The Pulp Drying System designed by ANDRITZ is a new and innovative system that combines selected areas of development into one complete, reliable, high-performance drying line.

“The good times are returning” according to Oliver Lansdell, Director, Hawkins Wright, provider of market intelligence and analytical services to the international pulp, paper, and biomass industries. And it seems the pulp industry, in particular, is enjoying something of a renaissance. There are various reasons for this optimism, including increasing demand for virgin fiber content in tissue and hygiene products, the exciting growth of renewable packaging, and strong demand in niche applications such as wood-based textile fibers and other new markets in the bioeconomy.

Innovative GPS navigates shortest route to fiber quality at lowest cost. Like your smartphone's GPS can guide you almost anywhere in the world, the "papermaking GPS" guides you in making the right choices about fiber mix, applied energy, and paper quality. It’s significantly reducing trial and error on your machine and saving time and money.

Södra Cell is one of those far-sighted northern European pulp producers that is constantly looking for ways to become fossil-fuel free and to make high-grade products in the most environmentally sound ways possible. ANDRITZ recently aided Södra Cell towards its sustainability target by supplying the latest in evaporation plant technology to its Mörrum mill in southern Sweden.

Improving pulp mill operation with Digital Twin technology