Harri Makkonen took over as Arauco MAPA Project Director for ANDRITZ on October 1, 2018. In July 2019, Makkonen moved to Concepción, Chile, together with his family after accepting the demanding challenge of being ANDRITZ Project Director for Arauco’s huge MAPA project. Makkonen’s family includes his wife Susanna and his 18-year-old daughter Matilda. Both support him in every way they can, and Makkonen is delighted to have his family with him in Chile.

Did you know that ...

ANDRITZ Brasil again won ABTCP “Best of the pulp & paper industry” awards?

Every year, ABTCP (Associação Brasileira Técnica de Celulose e Papel – the Brazilian Pulp and Paper Technical Association) honors companies that have contributed substantially to technological developments in the pulp and paper industry.

ANDRITZ Brasil has received the best manufacturer award in two categories of this year’s ABTCP Awards; for Machines and equipment for pulp production (for the fifth consecutive year) and Equipment and systems for liquor recovery and energy generation (for the second consecutive year).

Stora Enso’s Imatra Mill, located in eastern Finland, is one of the world’s largest producers of liquid packaging board. Now, thanks to the latest ANDRITZ flash drying technology, the mill is also able to fully utilize its BCTMP plant, which can now produce dry pulp for its internal use, as well as for the market.

CMPC Biopackaging – Boxboard and ANDRITZ have been collaborating successfully on ramping up mechanical pulp production for a number of years. The mill has gone from strength to strength, increasing capacity, to supply the demanding global market for high-quality, lightweight, folding boxboard.

Due to its perfect climate for fiber growth, Chile has become a major pulp and paper making nation over recent decades, with some of the world’s largest producers now situated in the South American country. ANDRITZ has also grown its base in Chile, and now offers complete equipment sales, project management, service, and maintenance support for its thriving pulp and paper mills.

The recovery boiler smelt spout area is an unwelcoming and potentially dangerous place to work. However, essential regular tasks need to be carried out in the area for efficient and smooth operation of the boiler. A combined team of ANDRITZ design experts and workshop engineers have come up with a smart solution, the Smelt Spout Cleaning System, that enables essential work and maintenance to take place in a harsh environment.

A closer look at the way roll covers, spreader rolls, SMART™ technology and Rezolve predictive analytics improve paper machine productivity, enhance product quality, and reduce operating costs. In October 2018, ANDRITZ and Xerium Technologies merged to form the ANDRITZ Fabrics and Rolls division. This new entity combines an extensive portfolio of pulp and paper machinery with the high-quality and customizable consumable products (such as machine clothing and roll technology) developed by Xerium. Creating a product-specific custom fit between machinery and the consumable products used by that machinery can generate tremendous value in the form of improved productivity, enhanced quality, and reduced operating costs. Now, with 30 global facilities producing customized roll and machine clothing technology solutions, ANDRITZ Fabrics and Rolls customers can equip their new or rebuilt machines for optimal performance more easily than ever before.

In Spectrum, we often have the privilege of reporting on new technological breakthroughs. But in this article about upgrading BM1 at PJSC Kyiv Cardboard and Paper Mill in Ukraine, that is not so much the focus. The new shoe press and calender from ANDRITZ have brought gains, true, but what was arguably most interesting in this case was …

ANDRITZ recently supplied the very first Bubbling Fluidized Bed (BFB) biomass boiler to the country of Denmark, which will assist in nationwide efforts to reduce CO2 emissions. The new boiler is installed at Helsingør Kraftvarmeværk’s new district heat and power generation plant, which is immaculate in design as well as operation.

Arauco’s MAPA project in Horcones, Chile is now in full swing; the earthmoving and foundation building has almost been completed and the civil works have started. ANDRITZ is a major supplier to the project and has been closely working together with Arauco, which will see the Chilean company become the third largest producer of eucalyptus pulp in the world. Start-up is scheduled for the first quarter of 2021.

An innovative concept – ANDRITZ Screen Booster – helps any mill upgrade the performance of its Screen Room. The Booster modules – Basket, Bearing Unit, Rotor, and Dilution Rotor – were created to enhance any of four critical components in a screening system. Any one, or all, of these upgrades can be easily installed on a screen as needed, regardless of the original equipment manufacturer.

Customers confide in us that a major source of pain is being locked into a single automation supplier with a control system that cannot be easily upgraded. Why can’t it be like their smartphone with an App Store where they can download and add functions with ease?

ANDRITZ is regarded as an innovator in developing technologies for the manufacture of premium tissue grades that are in high demand today. Yet the majority of the world’s tissue is produced using conventional dry-creping techniques. To serve this large market, ANDRITZ continually enhances the reliability and performance of its “standard” technology.

ANDRITZ has designed a broad range of high-consistency (HC) refiners to meet the demands of pulp, paper, panelboard, and recycle producers. At the top of the line in terms of throughput and motor power is the TX68 twin refiner.

The downturn in global manufacturing activity during the last year has created a difficult demand environment for many packaging grades. However, this is expected to be relatively short lived, since there are several factors that suggest better times are ahead, once the uncertainty on the manufacturing front eases. Global demand for packaging paper and board should grow 2.4% annually during the next five years, even if conditions remain challenging in 2020.

ANDRITZ is always exploring ways to take the ever-important issues of Health & Safety to new levels. We have recently launched the internationally recognized IOSH Managing Safely courses for all employees engaged in responsible positions within our pulp and paper activities around the globe. The Institution of Occupational Safety and Health (IOSH) is an international chartered professional body for Health & Safety in the workplace.

The production area of Turkish specialist nonwovens producer Sapro is more like a group of clinical laboratories than the production hub of one of the world’s largest producers of wet wipes. And it’s not just super clean; the company has embarked on a journey utilizing Metris solutions that will see it become one of the most efficient wet wipe producers in the industry.

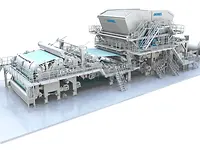

Wood, pulp, and paper have long determined the fortunes of the Pöls community in Styria. Here Zellstoff Pöls AG produces longfiber sulfate pulp and kraft papers. With an additional production line based on the exceptional ANDRITZ PrimeLine paper machine, the Heinzel Group site is now focusing more than ever on the world market.