Arauco’s MAPA project in Chile represents not only the most important expansion the company has ever undertaken, it is also currently the only major eucalyptus pulp project taking place in the world. The company operates five mills in Chile, one in Argentina, and has a joint venture in Uruguay, together with Stora Enso.

Did you know that ...

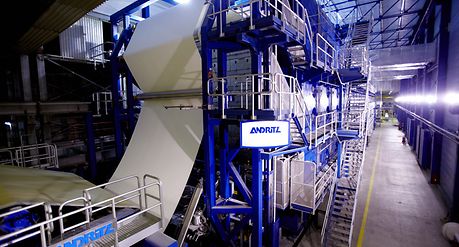

ANDRITZ pulp drying line at Altri Celbi achieved once again groundbreaking production world record?

Celbi was started up successfully after extensive reconstruction in 2015 and has achieved several production records since then. On March 23, 2019, Portuguese pulp producer Celbi set an outstanding production world record of 2,456 admt/d at its Leirosa mill, Portugal. In terms of specific drying capacity, Celbi thus achieved 503.3 tons per day and meter of working width on the ANDRITZ drying plant of 4.88 meters sheet width.

Get more information at: