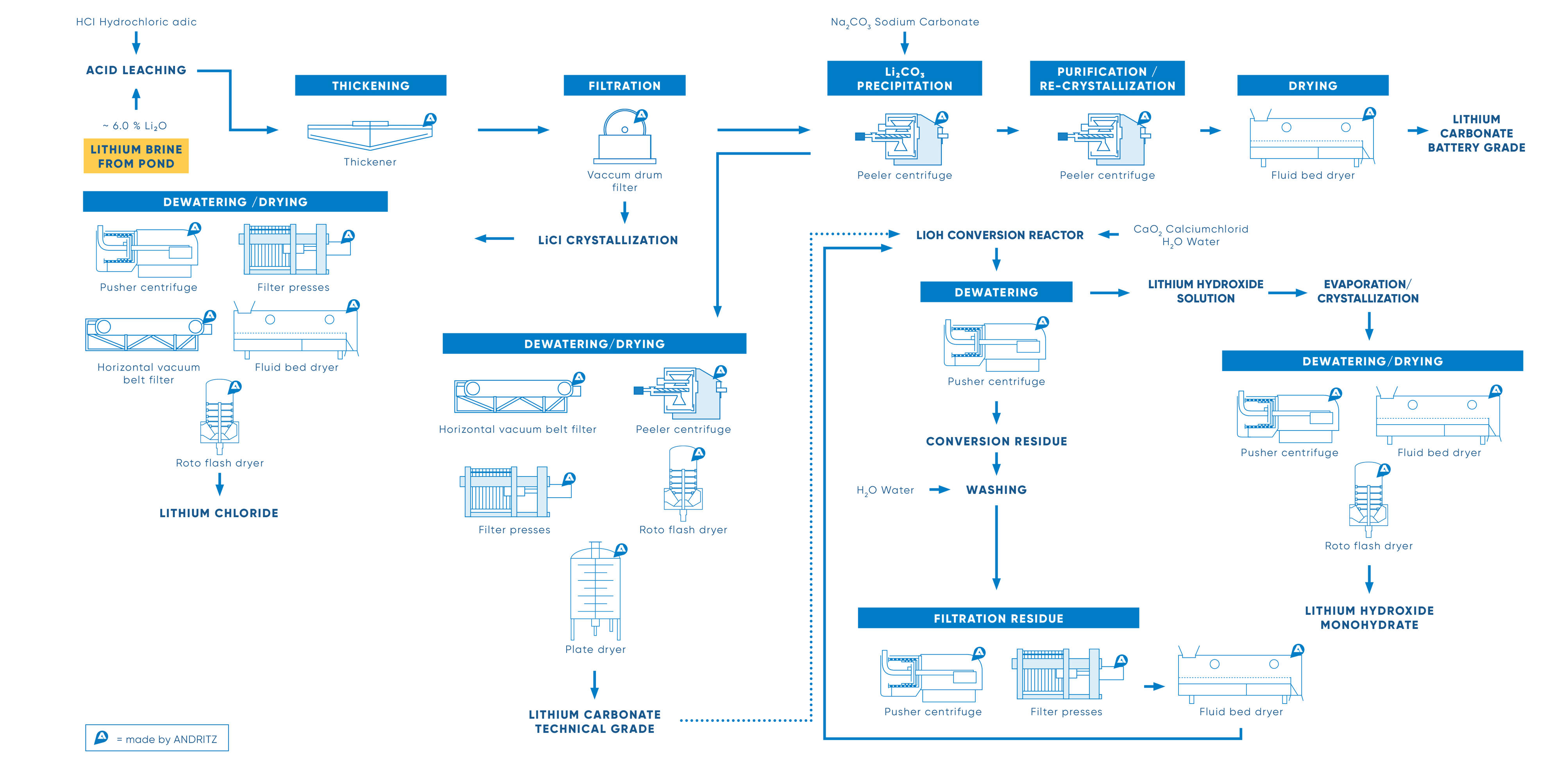

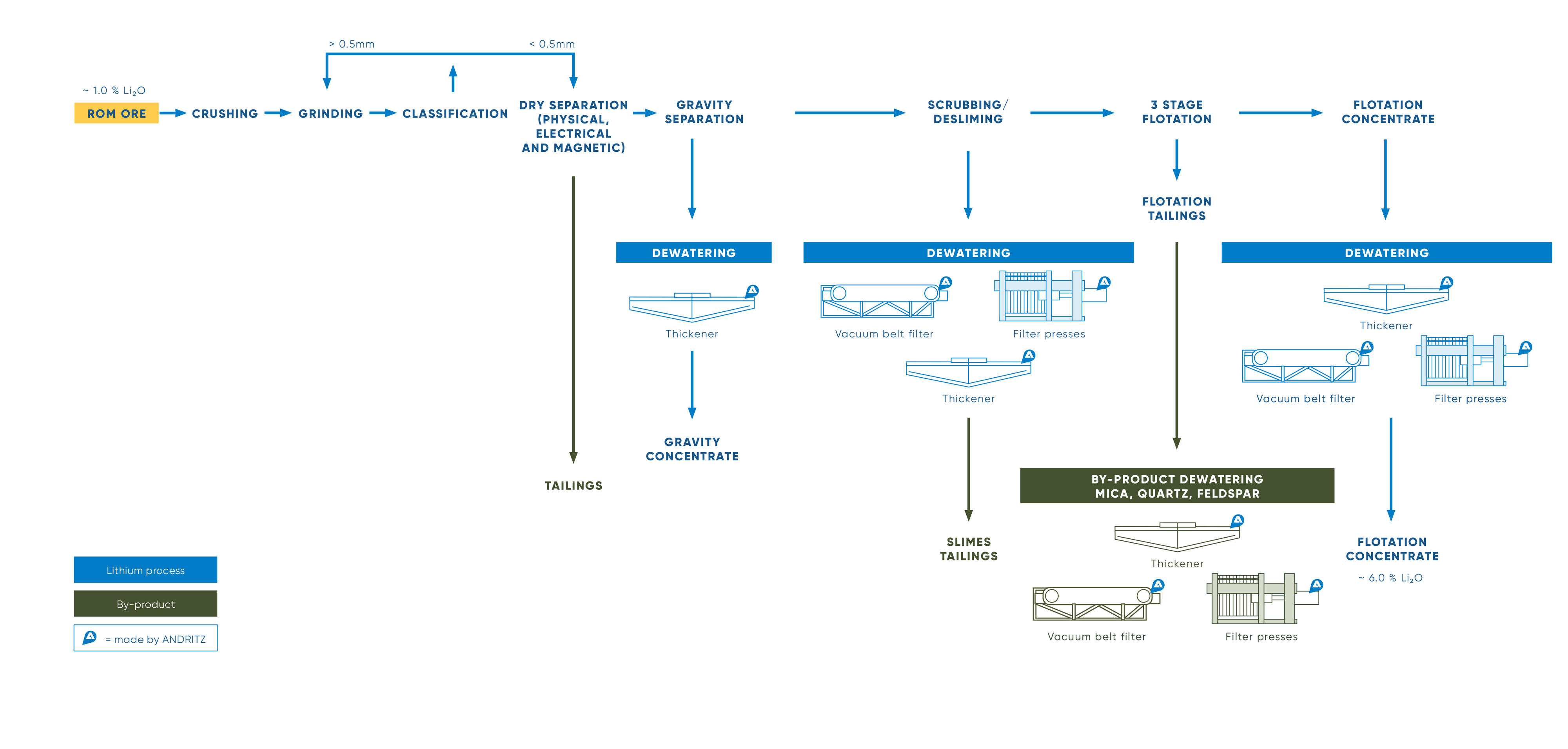

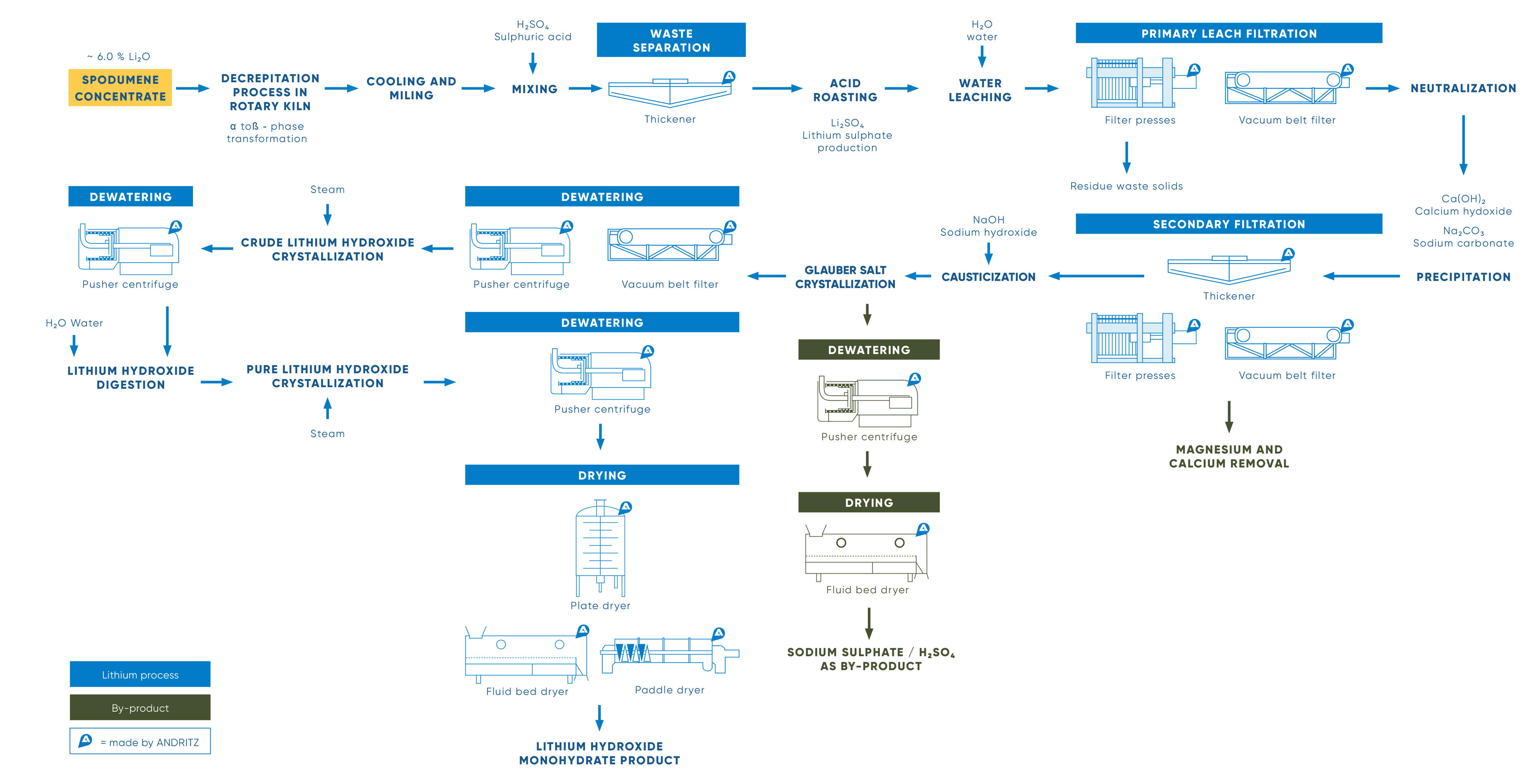

It all started in the 1960s, the first ANDRITZ pusher centrifuge for lithium carbonate, which operated for over 60 years. This represents our commitment to supplying the world’s largest lithium producers with robust separation technologies that withstand a long lifetime of continuous use. For hard rock lithium sources, we offer solutions for the thickening and dewatering for both tailings and spodumene at the mine site, as well as systems for the production of lithium hydroxide and lithium carbonate and the removal of impurities at the process plant. Combined with automation and digitalisation technology and proven local service, we are proud to be able to offer the full package from from simulation to installation and process optimization.